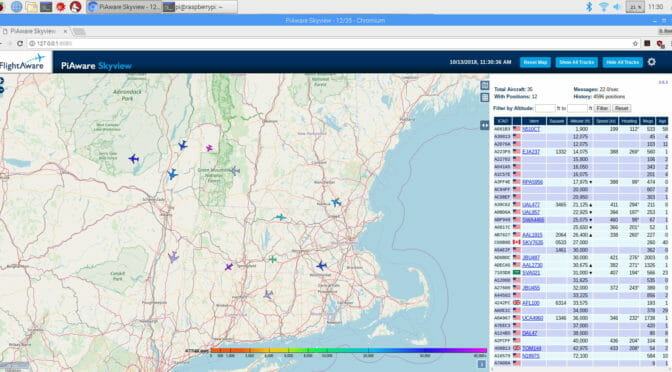

Flight Tracking

December will bring Thomas Kavanaugh, KC1ELF, for a presentation on Plane Tracking with ADS-B. This is something you can do in your own shack for very little cost if you’re willing to do a little work. Mr. Kavanaugh will provide us with a great overview in December’s General Meeting, and I’ll follow that up with a Tech Night RTL-SDR Workshop where we’ll make, among other things, a software defined radio to receive ADS-B signals.

In this article I’m going to show you how to make an antenna for ADS-B using just a little coax with a BNC connector, a bottle cap, a little wire, and a hot glue gun.

Designing an antenna for 1090 MHz

ADS-B is transmitted on 1090 MHz. For most of us, that frequency range is outside our experience. Fear not. Everything you know about making a dipole still works for this. The frequency is 1080 MHz so the length of each side of the dipole should be 234/1080 = 0.217 feet, or 2.6 inches. Not very big!

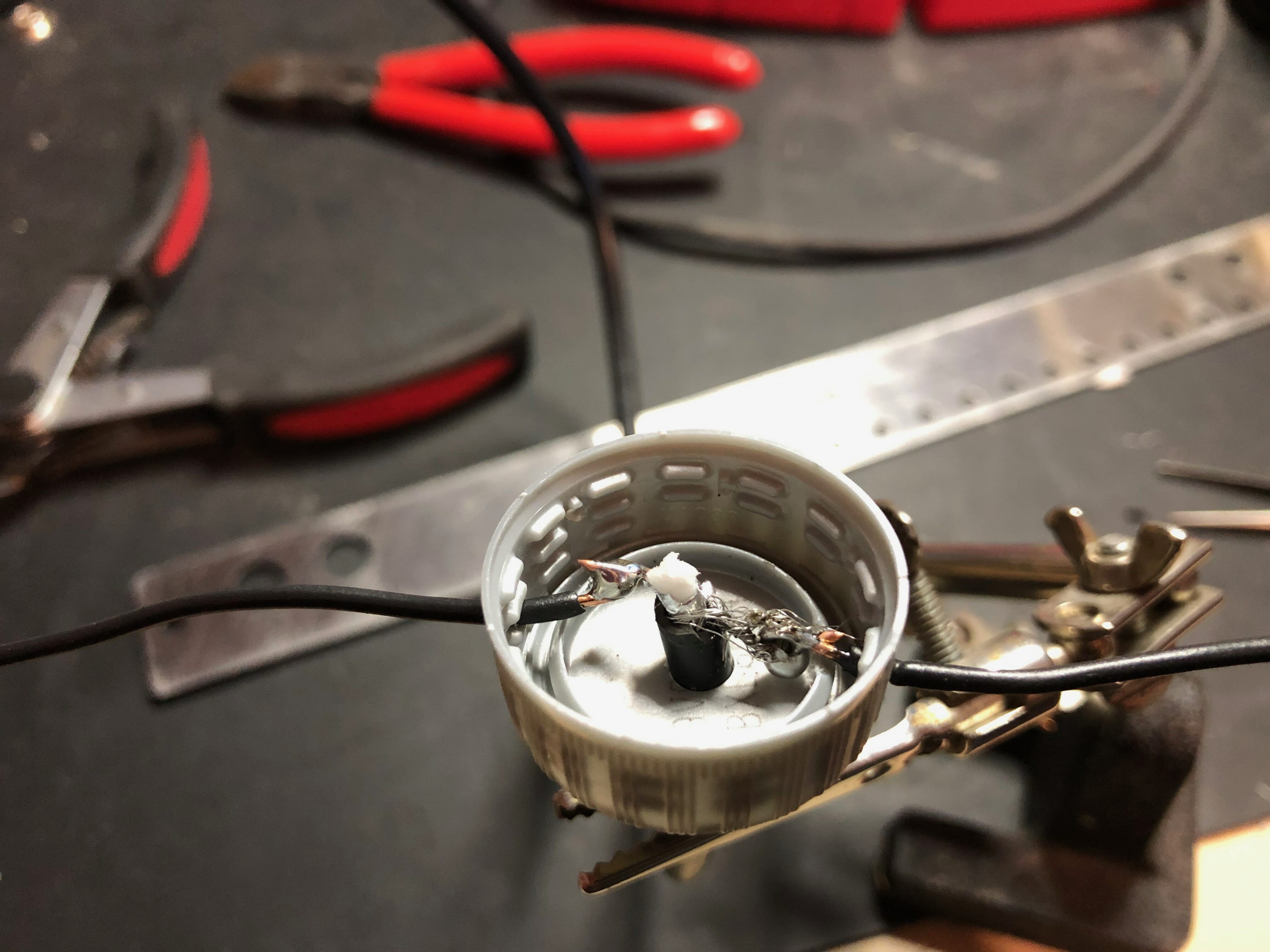

An antenna that small needs to have something solid to hold it to the coax. Below is my solution. I cut two wires to a little more than 2-1/2 inches in length. Then I took a plastic bottle cap and drilled holes for coax through the top and the two wires on the side. Figure 1 below shows this partially assembled.

Figure 1. Coax to dipole wire connections.

I began with a short coax jumper fitted with two male BNC connectors. I just cut one of the connectors off and fed the bare end through the top of the bottle cap. Then I soldered the short wires to the center conductor and braid of the coax. It was a tight fit in there, and the braid of this coax really didn’t like to be soldered, but the final connection was good enough to proceed.

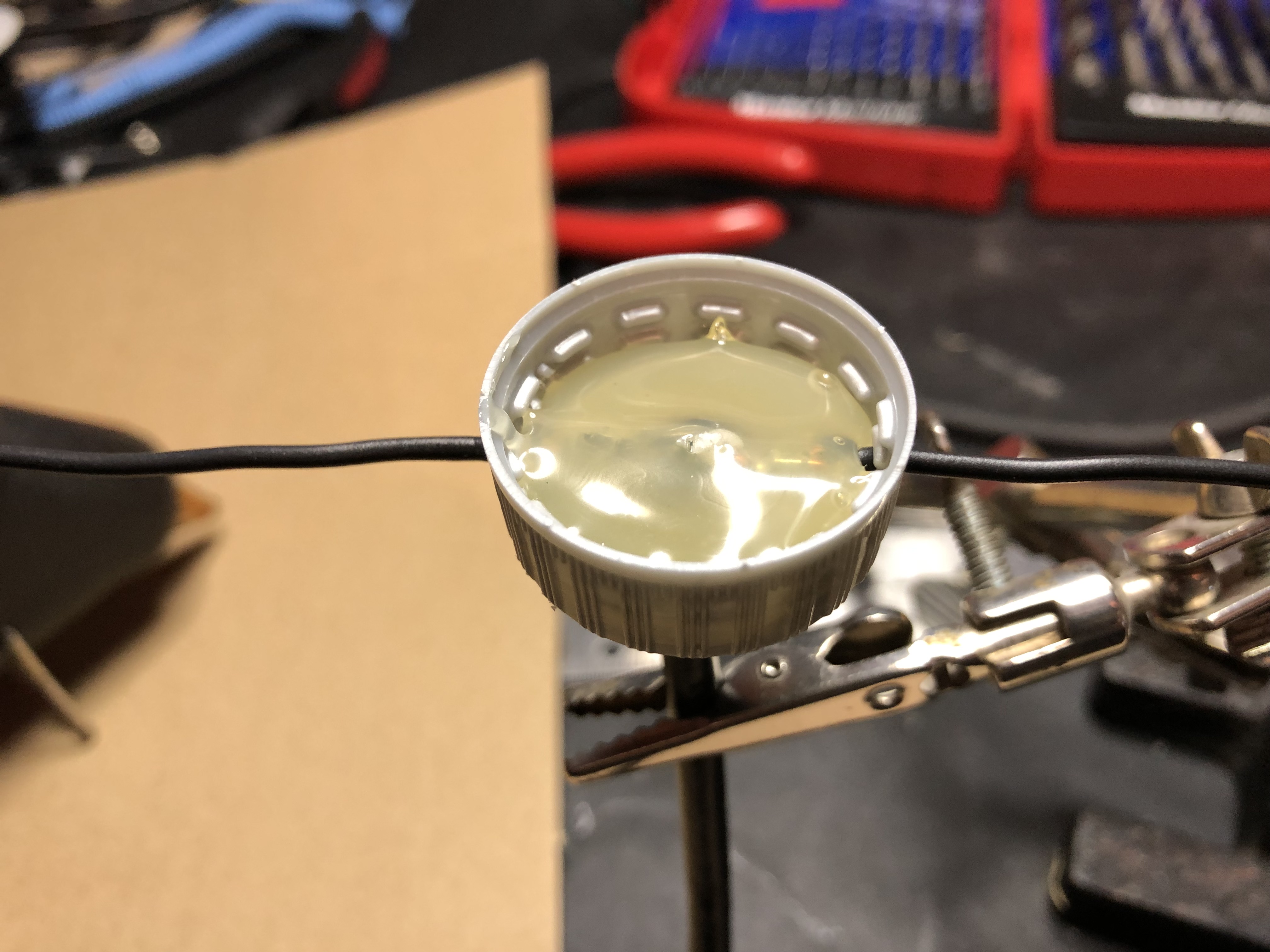

Finally, we want to fix all these connection into something solid. For that I used a hot glue gun to partially fill the bottle cap. This is shown in Figure 2 below.

Figure 2. Connections potted with hot glue

Installing the antenna

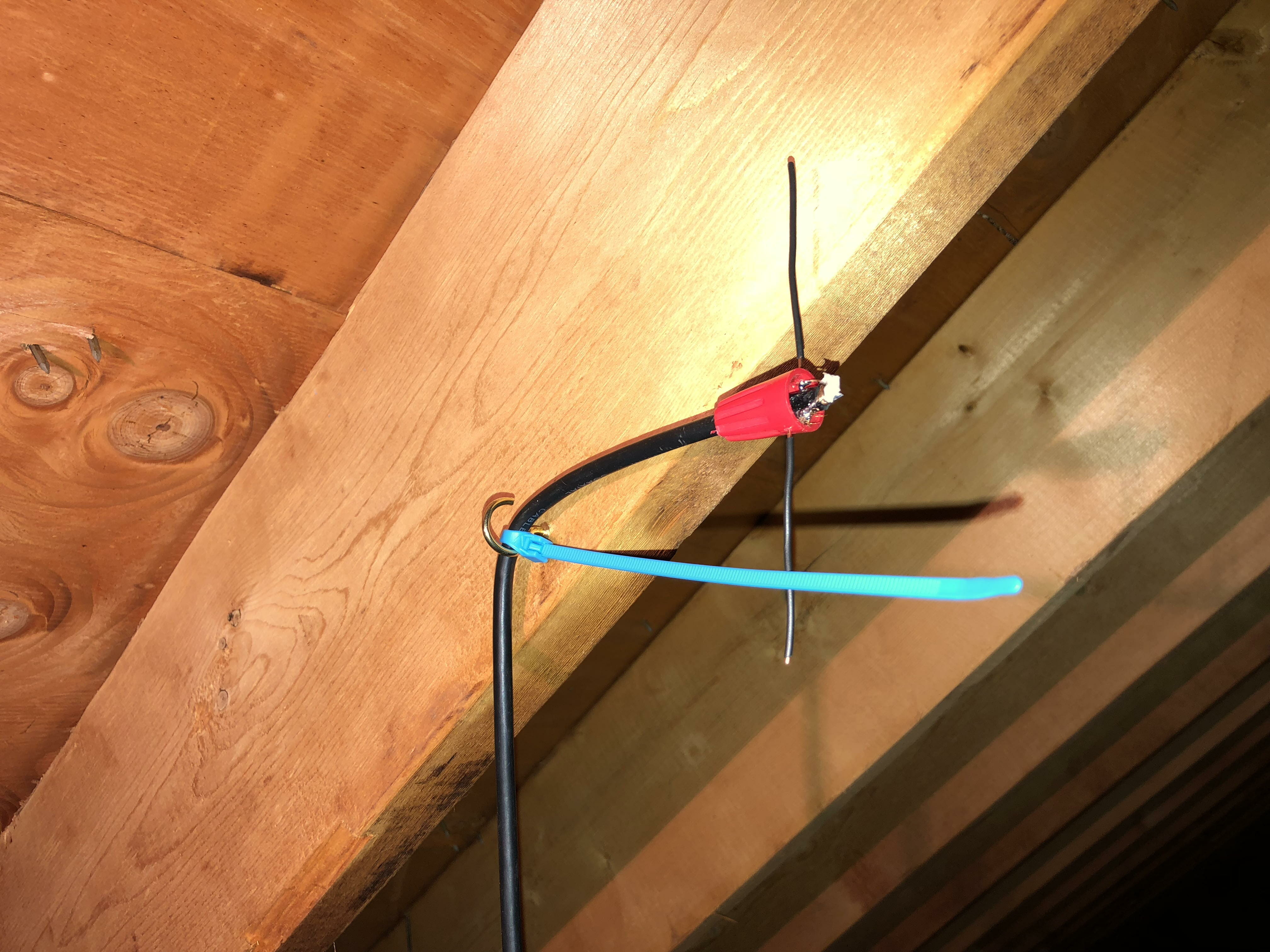

ADS-B transmissions are vertically polarized so it is important to hang the dipole with the elements in a vertical orientation. Here’s an earlier prototype of mine hanging in my attic. Just a single brass hook (and a zip tie) was all it took to get the antenna installed. See Figure 3.

Figure 3. Installing the antenna for vertical polarization.

Looking Ahead

I’ll be doing an article on building a Raspberry Pi computer capable of doing flight tracking later this month. It will need an antenna like this to work, though, so here’s your chance to do your homework early!

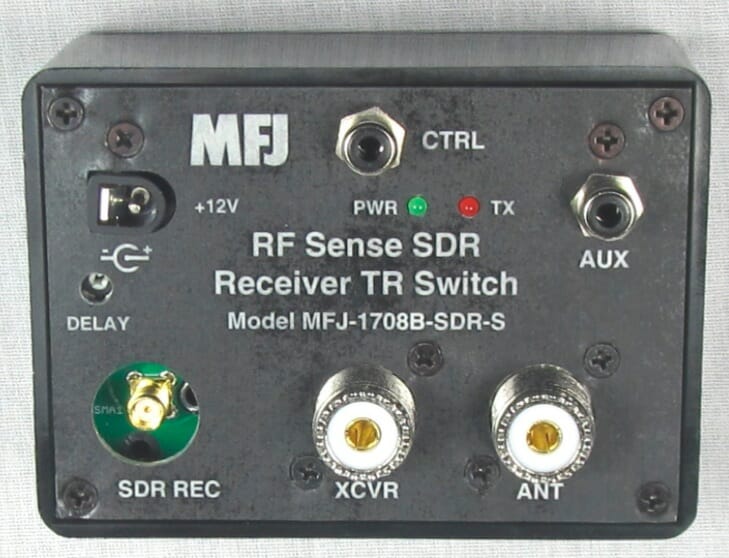

![Add SDR Capabilities to Your Radio [part 2]](https://www.n1fd.org/wp-content/uploads/2018/10/MFJ-1708B-651x372.jpg)