Introduction

End-fed half-wave (EFHW) antennas provide a convenient way to move the coaxial feedpoint for a half-wave antenna from the center to one end. There are three types of antenna feeds in popular use: 1) transformer feed, 2) L-matching network feed, and 3) Zepp.

The transformer feed variety may be broadband and, depending upon its construction may be useful over the entire HF spectrum. On the other hand, an L-matching network will only work on a single band. There are distinct advantages and disadvantages for each type of feed. This article will discuss the L-matching network feed in detail. The subject of ferrite transformer feeds will be discussed in detail in another article. The subject of Zepp antenna feeds is discussed in great detail in many antenna books [1]. One may think of a Zepp antenna as a folded full-wave antenna usually fed 0.25 wavelength from one end. When one unfolds the antenna, we have an off-center-fed (OCF), full-wave antenna. Depending upon the feed section, a single or double Zepp antenna may be designed to have the advantage of fundamental and harmonic operation.

If fed with an L-matching network, an EFHW antenna may possess an efficiency that exceeds 95%. Here are some things to consider when designing and using this antenna.

First, the load impedance at the end of the half-wave wire must be determined by iteration or through electromagnetic analysis. The load impedance will dictate the values of the L-matching network components. Parameters that have the greatest effect on load impedance are antenna height above terrain, physical properties of the antenna conductor, ground properties, and immediate surroundings.

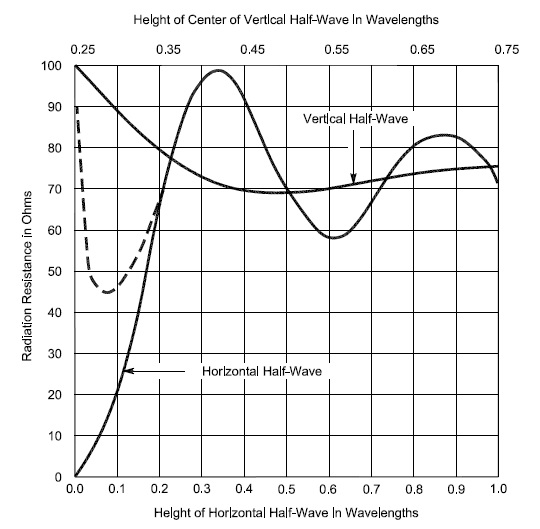

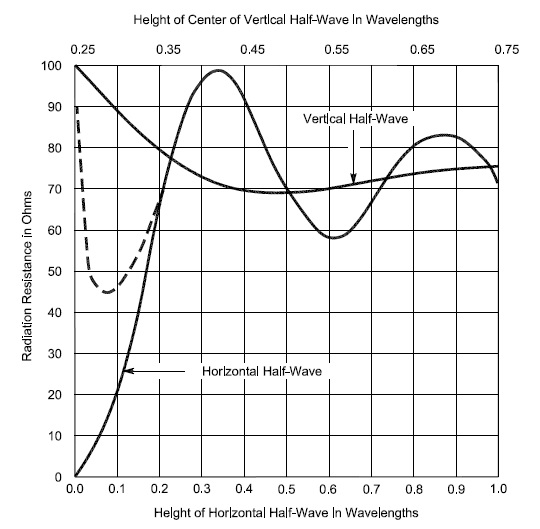

If we may digress for a moment, the radiation resistance of a center-fed half-wave dipole is well understood, and it varies with wavelengths above the terrain, as shown in Figure 1. For example, if we were to elevate a 40m dipole to 33′ (10m) above the terrain, we would expect a radiation resistance of about 80 ohms at the bottom of the band. This has been verified by modeling the antenna in EZNEC [2] (81.3 ohms) and by field measurement (78.8 ohms) [3]. One would expect the end resistance of a half-wave wire to vary in the same way, although at a vastly different impedance level.

Figure 1. Radiation Resistance of a Dipole Above a Perfectly Conducting Plane. Radiation resistance values for horizontal and vertical dipoles are shown as a function of wavelength above a perfectly conducting plane. The dotted line shows how the radiation resistance of a horizontal dipole departs from the graph when the dipole is close to real ground. It is expected that the end resistance of our EFHW antenna will follow similar variations as a function of wavelength above ground, although at very different impedance levels.

Figure 1. Radiation Resistance of a Dipole Above a Perfectly Conducting Plane. Radiation resistance values for horizontal and vertical dipoles are shown as a function of wavelength above a perfectly conducting plane. The dotted line shows how the radiation resistance of a horizontal dipole departs from the graph when the dipole is close to real ground. It is expected that the end resistance of our EFHW antenna will follow similar variations as a function of wavelength above ground, although at very different impedance levels.

This article will present test results measured at 5 frequencies in 5 bands to demonstrate how end resistances vary at a fixed height above terrain. We allow the number of wavelengths above ground to vary as a function of frequency while holding the antenna height constant. There is not enough test data to draw any conclusions other than to say that the end resistance appears to vary as a function of wavelength above the terrain. It is hoped that the measurement program will be completed as future work.

Second, if the antenna is fed close to where the radio operator will sit, as may be the case for portable operation, the electromagnetic fields at the end of the antenna may rapidly exceed those recommended by the FCC for controlled and uncontrolled environments. For this reason, it is recommended that both ends of the antenna be elevated, with the possible exception of QRP operation.

Third, any end-fed half-wave antenna will require a counterpoise. Sometimes, the counterpoise is provided by the coax that feeds the L-matching network, in which case the feedline will definitely carry common mode currents that will tend to spoil the antenna pattern of the half-wave wire. Since the coax that feeds the L-matching network steals current from the half-wave wire, it reduces the main-beam efficiency. This problem can be remedied by placing a common mode choke in the feedline at a distance of 0.05 wavelength [4] from the L-matching network. Since the common mode currents are on the outside of the shield, the value of 0.05 wavelength is measured in air, not in coax. Any effect due to the outer jacketing will be small. Be advised, however, that the 0.05 wavelength value is not cast in concrete. It is a starting point. To be absolutely sure, the currents on the transmission line shield, counterpoise, and antenna wire should be measured with an RF current probe. One such probe is the MFJ-854 [5]. As will be shown by electromagnetic analysis with EZNEC in another article, there will always be some RF currents where we don’t want them to be.

While a portion of the coaxial feedline may serve as a counterpoise, the alternative is to co-locate the common mode choke with the L-matching network so that a separate counterpoise wire can be connected to the L-matching network ground. In any event, the counterpoise conductor should be perpendicular to the half-wave radiator, regardless of whether it is horizontal or vertical, to minimize the interaction of counterpoise fields with the main antenna beam.

Methodology

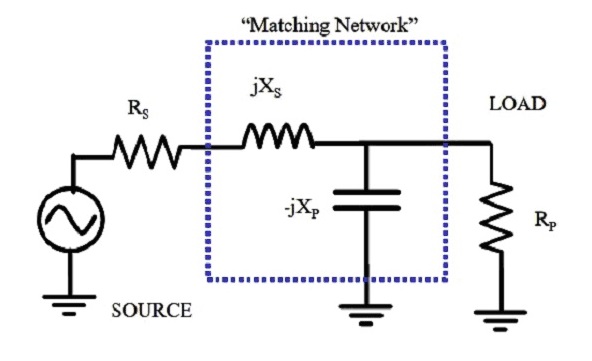

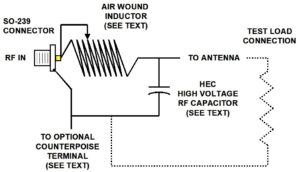

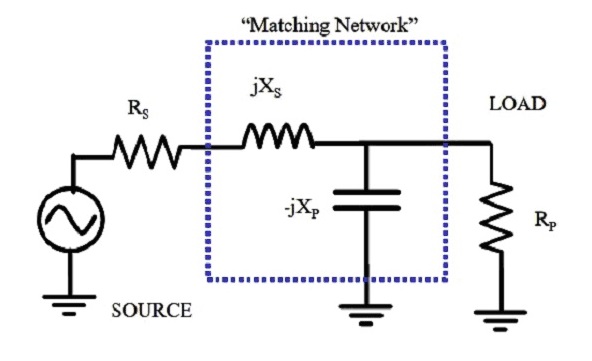

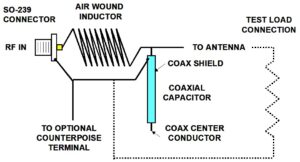

A lowpass L-matching topology is employed as shown in Figure 2 – a series inductor followed by a shunt, open-ended coaxial capacitor consisting of RG-316/U. (RG-316/U coax has a capacitance of 29 pf/ft.) It is widely known that if the shunt-matching element is in parallel with the load, the transformation will be from a higher load impedance to a lower source impedance [6]. This configuration is very easy to tune. However, this configuration will not bleed static charge from the antenna wire. While a series capacitor followed by a shunt inductor in parallel with the load will provide a similar transformation and static protection, this topology is more expensive to realize and more difficult to tune. We bring this point to your attention because static protection is often omitted from antenna installations.

The matching schematic below, and tutorial from Professor Stephen Long, Emeritus, ECE, UCSB, may be found online [7]. Figure 2. Lowpass Topology. The inductor may be air-wound or toroidally-wound, while the capacitor consists of an open-ended piece of RG-316/U. While the capacitor appears to be grounded at the bottom of the capacitor, for this implementation, the ground connection is soldered to the shield-end closest to the inductor. Rs is the 50-ohm source impedance, real, while Rp is the antenna end impedance, real.

Figure 2. Lowpass Topology. The inductor may be air-wound or toroidally-wound, while the capacitor consists of an open-ended piece of RG-316/U. While the capacitor appears to be grounded at the bottom of the capacitor, for this implementation, the ground connection is soldered to the shield-end closest to the inductor. Rs is the 50-ohm source impedance, real, while Rp is the antenna end impedance, real.

An online calculator that performs all of the calculations for a variety of L-Matching Network topologies may be found on John Wetherell’s website [8]. While online calculators are great, the reader is encouraged to perform at least one calculation if only to verify that the calculator yields the same result as theirs.

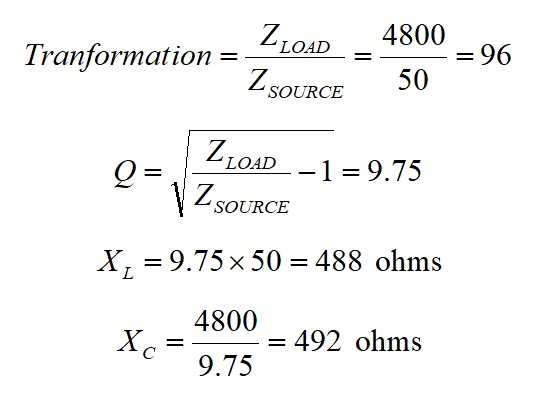

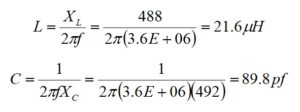

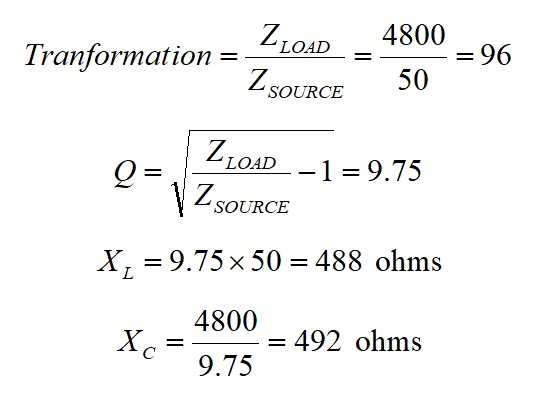

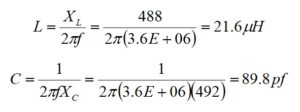

A quick way to arrive at the values for the matching elements is to estimate the impedance transformation ratio required. For example, if we needed to transform from a 50-ohm source to a 4800-ohm load impedance, the impedance transformation ratio would be 1:96. From that, we obtain the unloaded Q and the reactance values required. The unloaded Q = 9.75, and the reactance required for the inductor at the design frequency would be 488 ohms. The reactance required for the capacitor would be 492 ohms. If we were designing for 80m, we would calculate the inductance and capacitance from the reactance formulas at, for example, 3.6 MHz.

The unloaded Q = 9.75, and the reactance required for the inductor at the design frequency would be 488 ohms. The reactance required for the capacitor would be 492 ohms. If we were designing for 80m, we would calculate the inductance and capacitance from the reactance formulas at, for example, 3.6 MHz.

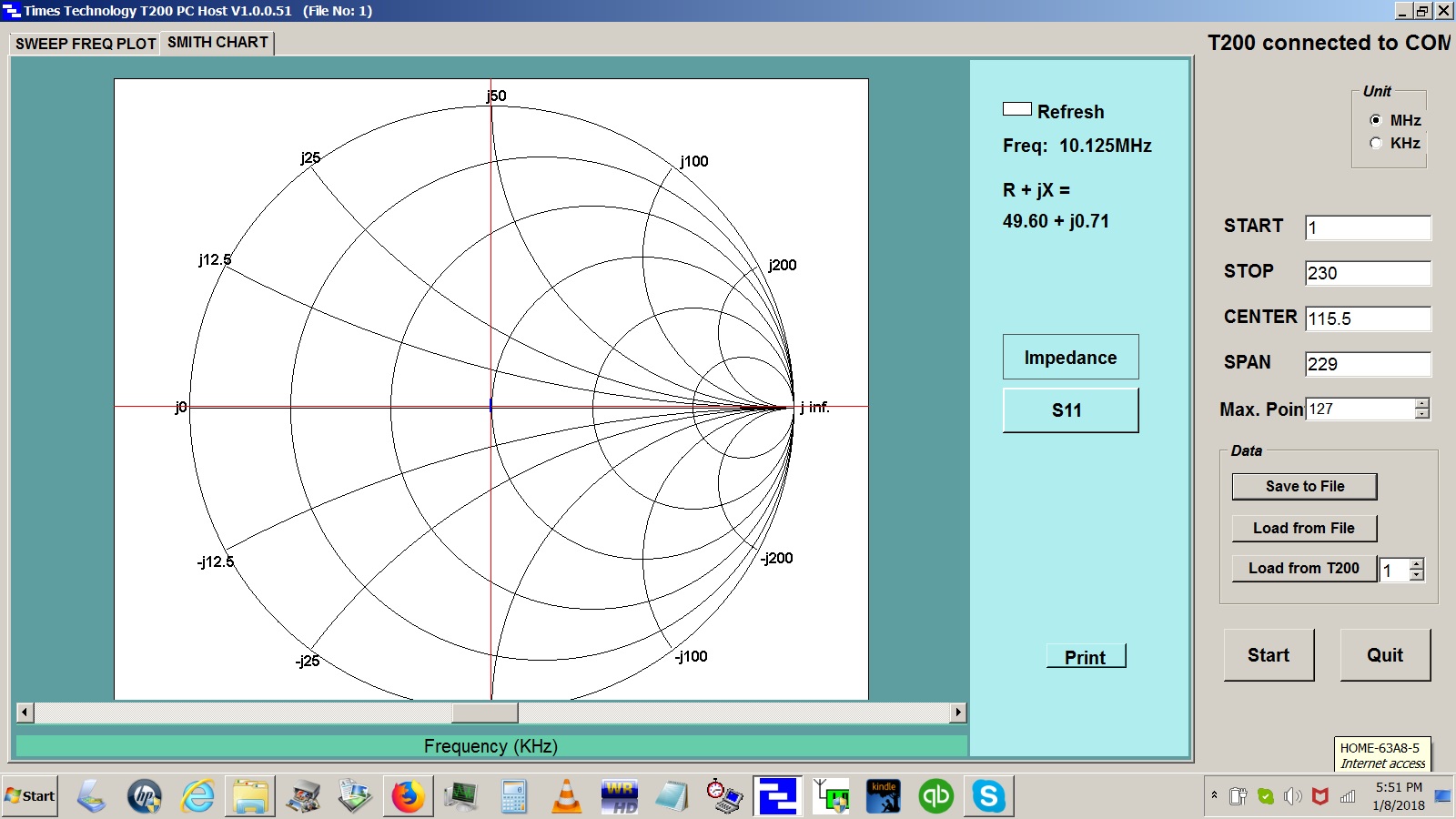

The series inductance would be 21.6 μH, and the shunt capacitance would be 89.8 pf. Then, we would build the network with a coaxial capacitor that had been cut too long and load the network with a 4800-ohm non-inductive resistor. An antenna analyzer would be connected to the network as the source, and the coaxial capacitor would be pruned a tiny bit at a time (it is easy to overshoot the mark) until the reactance at the design frequency had been canceled. If the antenna analyzer could be connected to a PC, tuning might be performed in real-time. A convenient display to use would be the Smith Chart view.

The series inductance would be 21.6 μH, and the shunt capacitance would be 89.8 pf. Then, we would build the network with a coaxial capacitor that had been cut too long and load the network with a 4800-ohm non-inductive resistor. An antenna analyzer would be connected to the network as the source, and the coaxial capacitor would be pruned a tiny bit at a time (it is easy to overshoot the mark) until the reactance at the design frequency had been canceled. If the antenna analyzer could be connected to a PC, tuning might be performed in real-time. A convenient display to use would be the Smith Chart view.

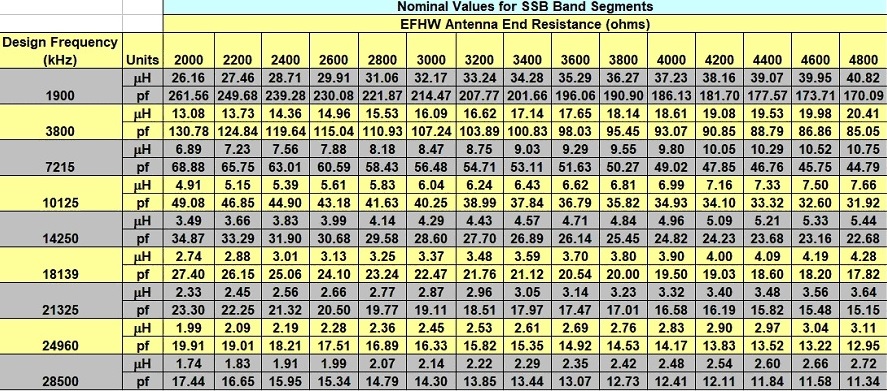

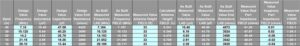

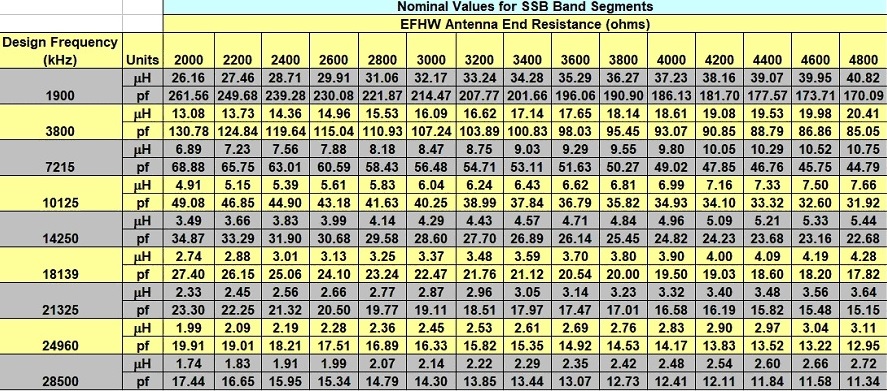

Two tables of component values at frequencies in commonly used ham bands are provided in Table 1 for CW and Table 2 for SSB. The tables are parametric and provide component values for a variety of EFHW antenna end resistances from 2000 to 4800 ohms.

A good starting value for any design is 3200 ohms, and in most cases, it will deliver satisfactory results. One need not rely upon the design frequencies in the tables. You now have all tools that you need to design networks for any frequency and any load impedance! Table 1. CW Band Segment Component Values as a Function of End-Fed Half-Wave Antenna End Resistance.

Table 1. CW Band Segment Component Values as a Function of End-Fed Half-Wave Antenna End Resistance. Table 2. SSB Band Segment Component Values as a Function of End-Fed Half-Wave Antenna End Resistance.

Table 2. SSB Band Segment Component Values as a Function of End-Fed Half-Wave Antenna End Resistance.

Determining Component Values

Access to an Inductance-Capacitance-Resistance (LCR) meter is highly desirable to ensure that the L-matching networks are being built to the design values. Fortunately, these instruments have become inexpensive and accurate, and they are quite useful for identifying unknown component values.

Implementation

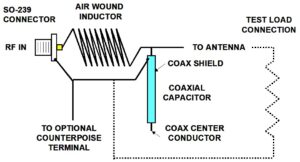

A 30m L-matching network test article that employs an air-wound inductor is depicted in Figure 3. The sketch in Figure 4 shows the network interconnects in greater detail. The final iterated load impedance was 3024 ohms, the inductance value was 6.16 μH, and the final capacitance value was 41.7 pf. The resulting VSWR was 1.04:1 at 10.133 MHz. The air inductor was been wound on a scrap length of ½” PVC conduit. The OD of this conduit is 0.840” (21.34mm). The inductance wound for this test article consists of 22 tightly-wound turns of #20 AWG enameled magnet wire, but #18 AWG is highly recommended for the final L-matching network. Hot glue was used to hold the turns together during tests, but non-corrosive silicone is recommended once the inductance has been finalized. You can use an online calculator to estimate the number of turns required for the air-wound inductor of a specific diameter and length [9], but please use an LCR meter for precision. The capacitor consists of an open-ended piece of RG-316/U coax that was chosen for its maximum voltage rating of 1,200 volts and 29 pf/foot capacitance. The approximate length of our coaxial capacitor is 17 inches. In a separate article, we will discuss voltage requirements for transmission lines when subjected to elevated VSWR.

Figure 3. Lowpass L-Matching Network Topology for 30m Test Article. The air-wound inductor consisting of #20 AWG enameled magnet wire is connected from the center conductor of the SO-239 UHF connector straight through to the antenna terminal. Hot glue holds the turns in place. The coaxial capacitor center conductor is connected directly to the antenna terminal. The other end of the coaxial capacitor remains open-circuited. The photo shows a short piece of clear shrink tubing that protects the open end of the coax (see text). A ground connection to the coaxial capacitor shield is soldered near the antenna terminal end of the coax with a piece of buss wire (see Figure 3). The other end of the bus wire is grounded to the flange of the SO-239 UHF connector with a solder lug. The housing is a Bud Industries PN-1320.

Figure 3. Lowpass L-Matching Network Topology for 30m Test Article. The air-wound inductor consisting of #20 AWG enameled magnet wire is connected from the center conductor of the SO-239 UHF connector straight through to the antenna terminal. Hot glue holds the turns in place. The coaxial capacitor center conductor is connected directly to the antenna terminal. The other end of the coaxial capacitor remains open-circuited. The photo shows a short piece of clear shrink tubing that protects the open end of the coax (see text). A ground connection to the coaxial capacitor shield is soldered near the antenna terminal end of the coax with a piece of buss wire (see Figure 3). The other end of the bus wire is grounded to the flange of the SO-239 UHF connector with a solder lug. The housing is a Bud Industries PN-1320.

Figure 4. Lowpass L-Matching Network with Air-Wound Inductor Interconnects. The sketch shows where an optional, separate counterpoise may be connected if the coax is not used as the counterpoise. It also shows where the ground connection is soldered onto the coaxial capacitor shield. The dotted lines show where to connect the test load resistor to the network.

Figure 5 shows the configuration for a 15m L-matching network test article. The magnet wire gauge used is #18 AWG because the inductor will fit the housing. Hot glue is used to keep the turns in place. The final inductance value is 2.91 μH, and the coaxial capacitor value is 20.7 pf. The test frequency is 21.09 MHz, while the end resistance is 3042 ohms. The uninsulated open circuited coax is visible. The braid and jacket must be pruned back and insulated to prevent RF arcing. A 1 pf capacitor is soldered in parallel with a coaxial capacitor to correct the capacitance. This capacitor combination was replaced with a longer piece of coax for the final configuration.

Figure 5. A 15m L-Matching Network Test Article. A 1 pf capacitor (visible in the white circle) is soldered in parallel with the coaxial capacitor to tune the network without changing the coax. The coaxial capacitor will have to be changed before transmitting because the capacitor is not rated for high RF voltage.

In order to prevent the coaxial capacitor from arcing from its center conductor to the shield near its open end, it is a good idea to snip back the coax shield a tiny bit near the open end. This has to be done while the coaxial capacitor is being tuned to its final value, however. Once one arrives at the final value, the end of the coax may be covered with a short length of shrink tubing to protect it. When tuning these networks for the higher bands, namely 20, 17, 12, and 10 meters, it may be beneficial to complete the tuning with the coax coiled in its final configuration. The pruning procedure can be somewhat fussy, and altering the capacitor configuration at the very end can lead to disappointing results.

From the network configuration, one can see that there is always access to the inductor and capacitor for measurement. It is a good idea to record the as-built values of the network once it has been tuned into the test load. Many times it will be found that the as-built values will not be exactly the same as the design values. The reason is usually the inter-turn capacitance of the air-wound coil. It’s alright as long as there is a good match into the test load resistor. We will explore the inter-turn capacitance in a separate article.

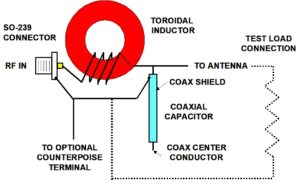

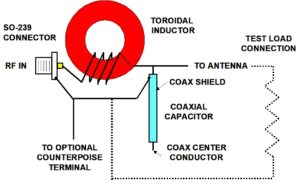

One final note on construction: The inductors for the 160, 80, 60, and 40m bands will require a large number of turns. If air-wound, they may be too long to fit within your enclosure. One solution has been to build the network in a bigger enclosure. That will preserve the low-loss properties of the L-matching network. There will be a separate article that describes the construction of a 600W L-matching network with an air inductor for 40m. For portable use, however, compactness may be a virtue, and you may wish to wind the inductors in some other way at the expense of some RF efficiency. For such cases, consider the use of small ferrite or iron cores. You will want to choose a core type for the frequency range of interest, most likely #2 (red) iron material [10] or #61 ferrite material [11]. The permeability of iron is much lower than it is for ferrite. More turns will be required on an iron core. You may also want to choose a core size that is large enough for several turns. If the core doesn’t have enough turns, it will be difficult to fine-tune the inductance. If there are too few turns, even a small adjustment will dramatically affect the inductance, and the required value will not be obtained. A 40m L-matching network that employs a toroidal inductor is depicted in Figure 6. The sketch in Figure 7 shows the network interconnects in greater detail. An FT114-61 ferrite core has been used for 40m. Eleven turns of #18 AWG magnet wire were required to obtain 10.4 μH. The coaxial capacitor consists of approximately 19” of RG-316/U. The inductance of the toroid may be altered by spreading and compressing the turns and/or by adding and removing turns.

Figure 6. Lowpass L-Matching Network Topology for 40m. The toroidal inductor is connected from the center of the SO-239 UHF connector straight through to the antenna terminal. The coaxial capacitor center conductor is connected directly to the antenna terminal. The other end of the coaxial capacitor remains open-circuited. A ground connection to the coaxial capacitor shield is soldered at the antenna terminal end of the coax with a piece of buss wire (see Figure 5). The other end of the bus wire is grounded to the flange of the SO-239 UHF connector with a solder lug. The housing is a Bud Industries PN-1320.

Figure 7. Lowpass L-Matching Network with Toroidal Inductor Interconnects. The sketch shows where an optional, separate counterpoise may be connected if the coax is not used as the counterpoise. It also shows where the ground connection is soldered onto the coaxial capacitor shield. The dotted lines show where to connect the test load resistor to the network.

The 80m L-matching network shown in Figure 8 was constructed with a T130-2 iron toroid core because the material was available. There are approximately 40 turns on the core for an Inductance of 21.3 μH. This core material permeability is 10, which is about one-tenth the permeability of #61 ferrite material. With so many turns, the inter-turn capacitance is apt to be large. For this design, an FT114 -61 core would be a better choice for fewer turns. This test article was built for a test frequency of 3.55 MHz with an end resistance is 4639 ohms. The coaxial capacitance value is 93.8 pf.

Figure 8. An 80m L-Matching Network. This network was constructed with a T130-2 iron core. The initial permeability of this core is too low, requiring too many turns with attendant inter-turn capacitance. The next iteration will employ FT114-61 material.

Lab Test Procedure

Once the design frequency and antenna load impedance have been chosen for the design, an L-matching network is fabricated. The network is loaded with a non-inductive load resistor (a cermet trimpot is a good choice), having the same value as our antenna load impedance design value. The network is connected to a vector antenna analyzer. If possible, the Smith Chart view should be utilized. Most vector antenna analyzers can be connected to a computer via USB, and a Smith Chart may be displayed in real-time. What we should see, if we sweep through the design frequency, is a display near the center of the Smith Chart. If the display is below the axis of reals for the Smith Chart, the coaxial capacitor will have to be pruned a bit at a time until the display at the design frequency is right at the center of the chart. Thus, the reactance has been canceled, and we are left with a perfect transformation from the load impedance to the characteristic impedance of 50 ohms. If we call for the reactance view on the vector antenna analyzer, we should be able to see the reactance pass through zero at the design frequency of the L-matching network. Finally, we disconnect the load resistor from the network and prepare for field testing.

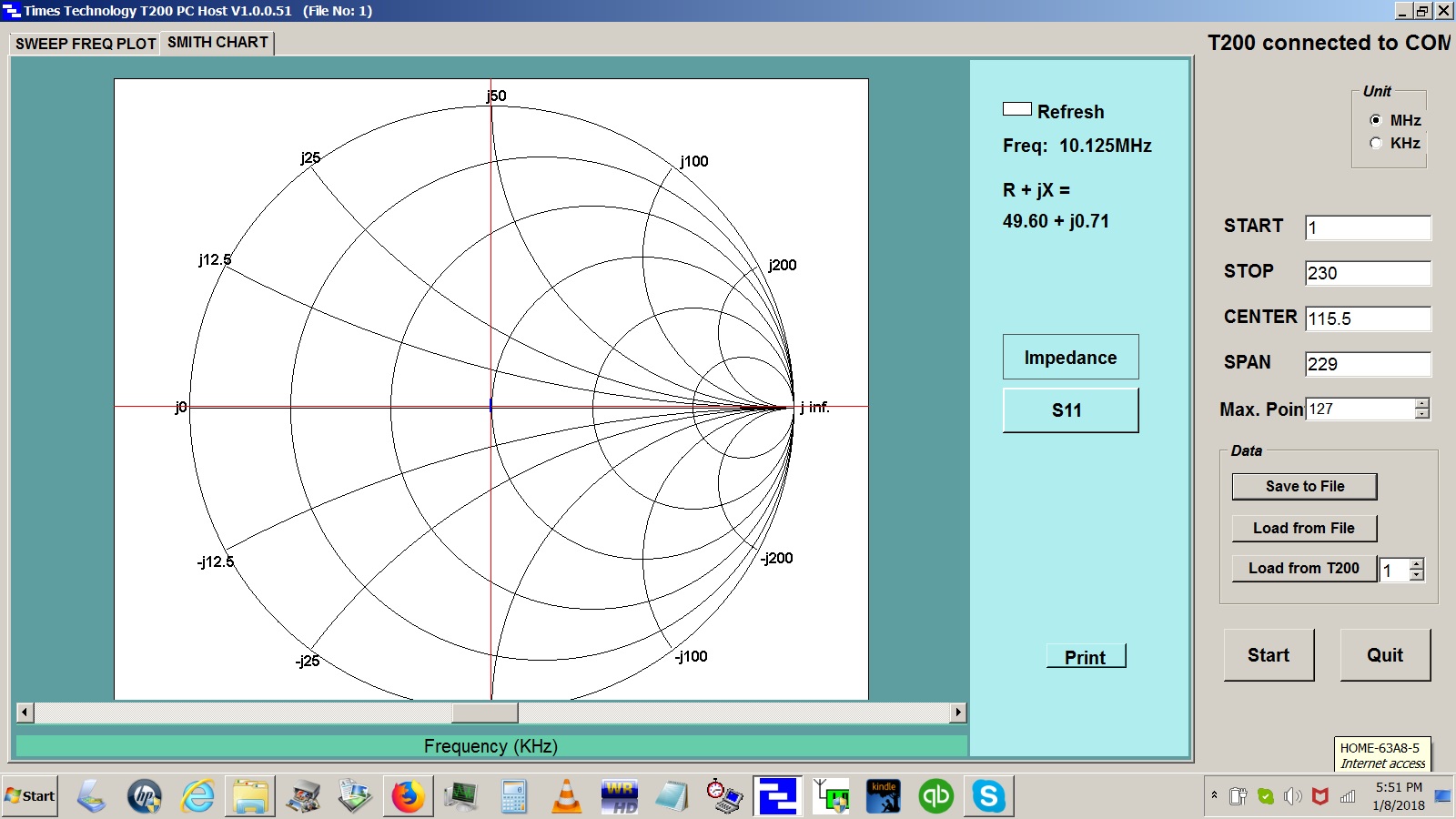

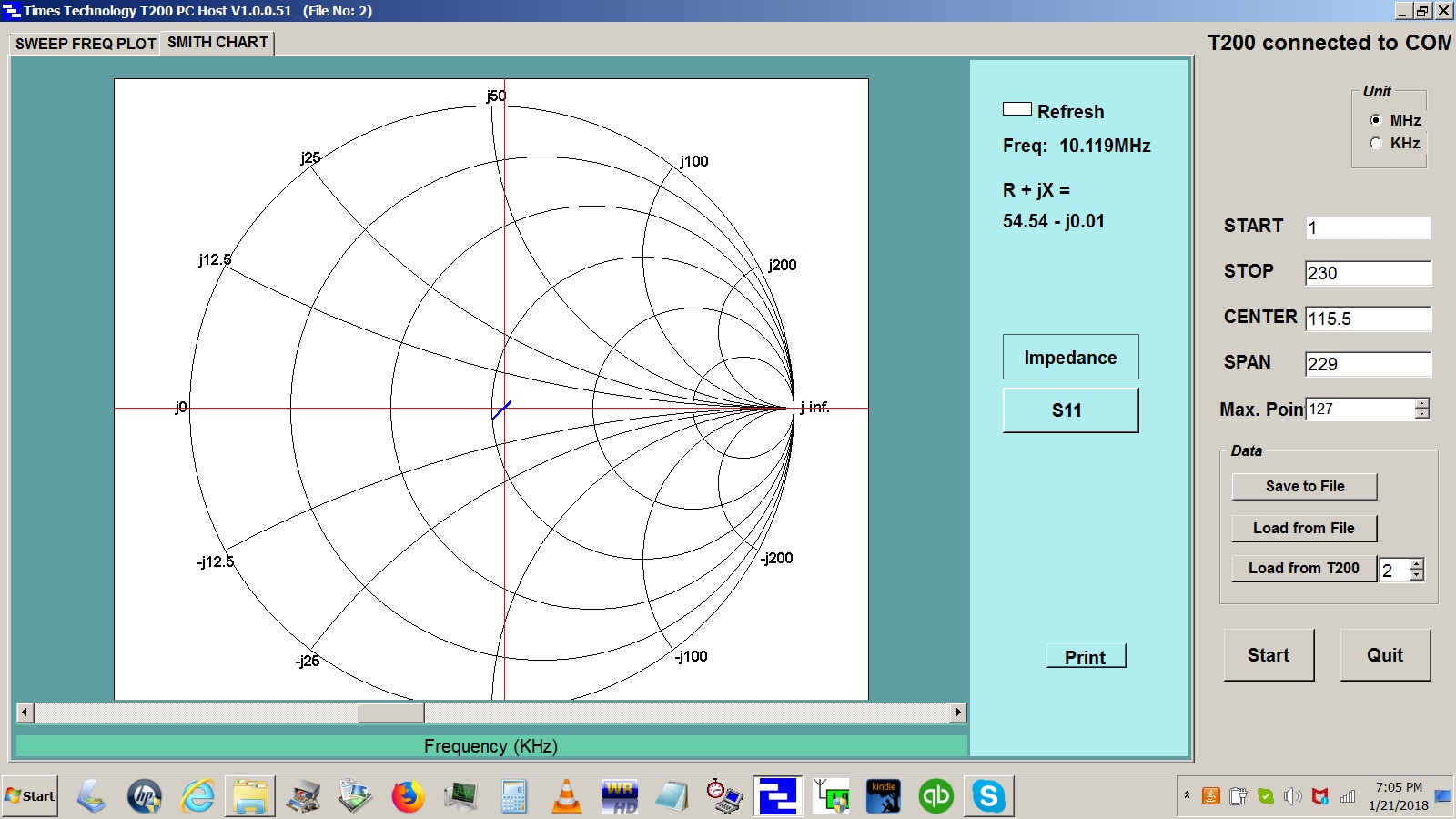

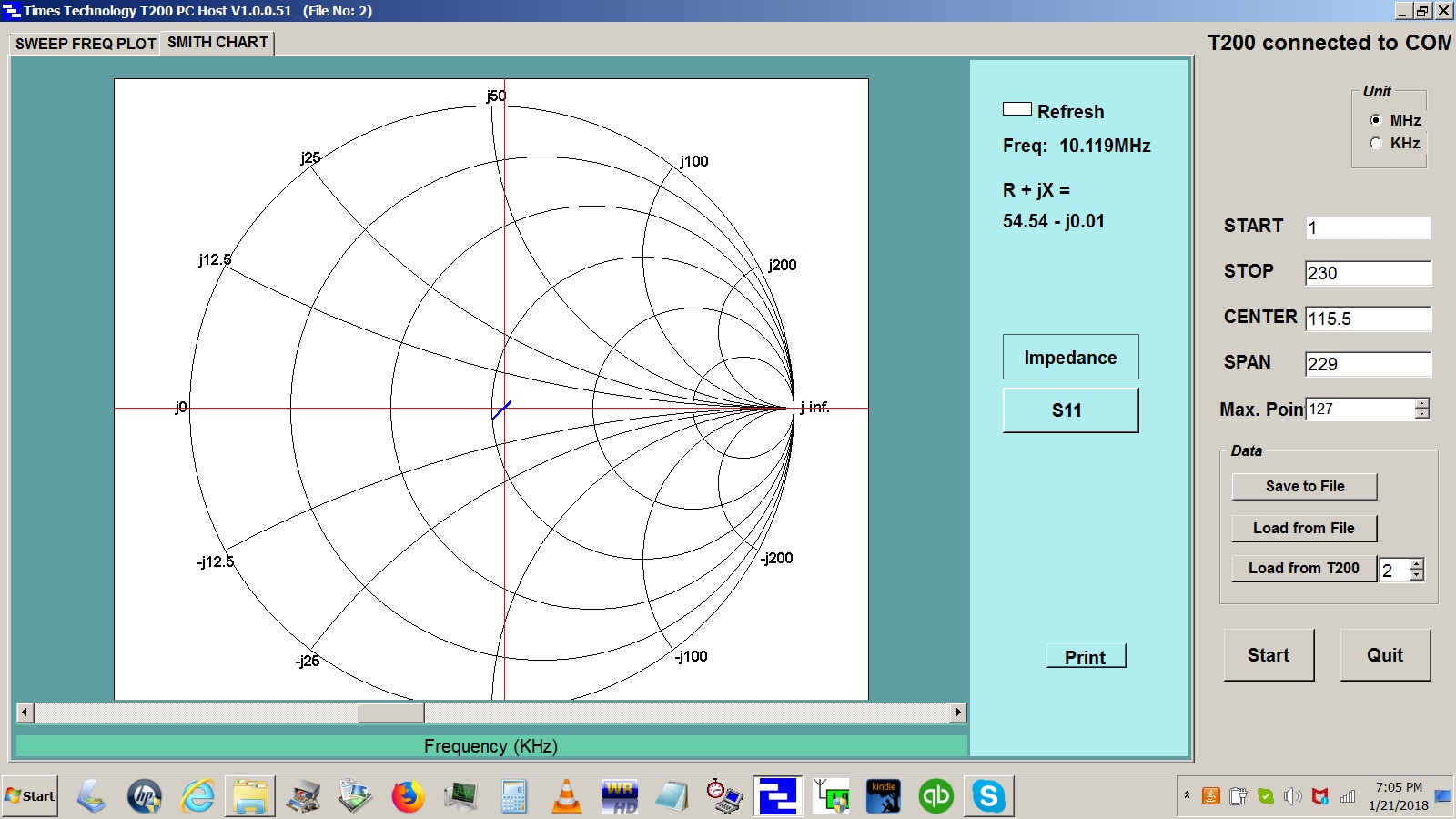

A Smith Chart for the 30m L-matching network is shown in Figure 9. Data was collected on an MFJ-226 Graphical Antenna Analyzer with the network connected to a 3024-ohm cermet trimpot test load. Once the inductance had been adjusted with an LCR meter, the coaxial capacitor was pruned until the reactance was canceled to place the cursor at the center of the Smith Chart. The network was designed to match 3000 ohms, and a slight adjustment of the trimpot placed the cursor at the center of the chart. Tuning is a bit tricky because the 30m Band is so narrow.

Figure 9. Lab Tuning of the 30m L-Matching Network. The inductor, capacitor, and test load are adjusted to place the cursor and the center of the Smith Chart.

Figure 9. Lab Tuning of the 30m L-Matching Network. The inductor, capacitor, and test load are adjusted to place the cursor and the center of the Smith Chart.

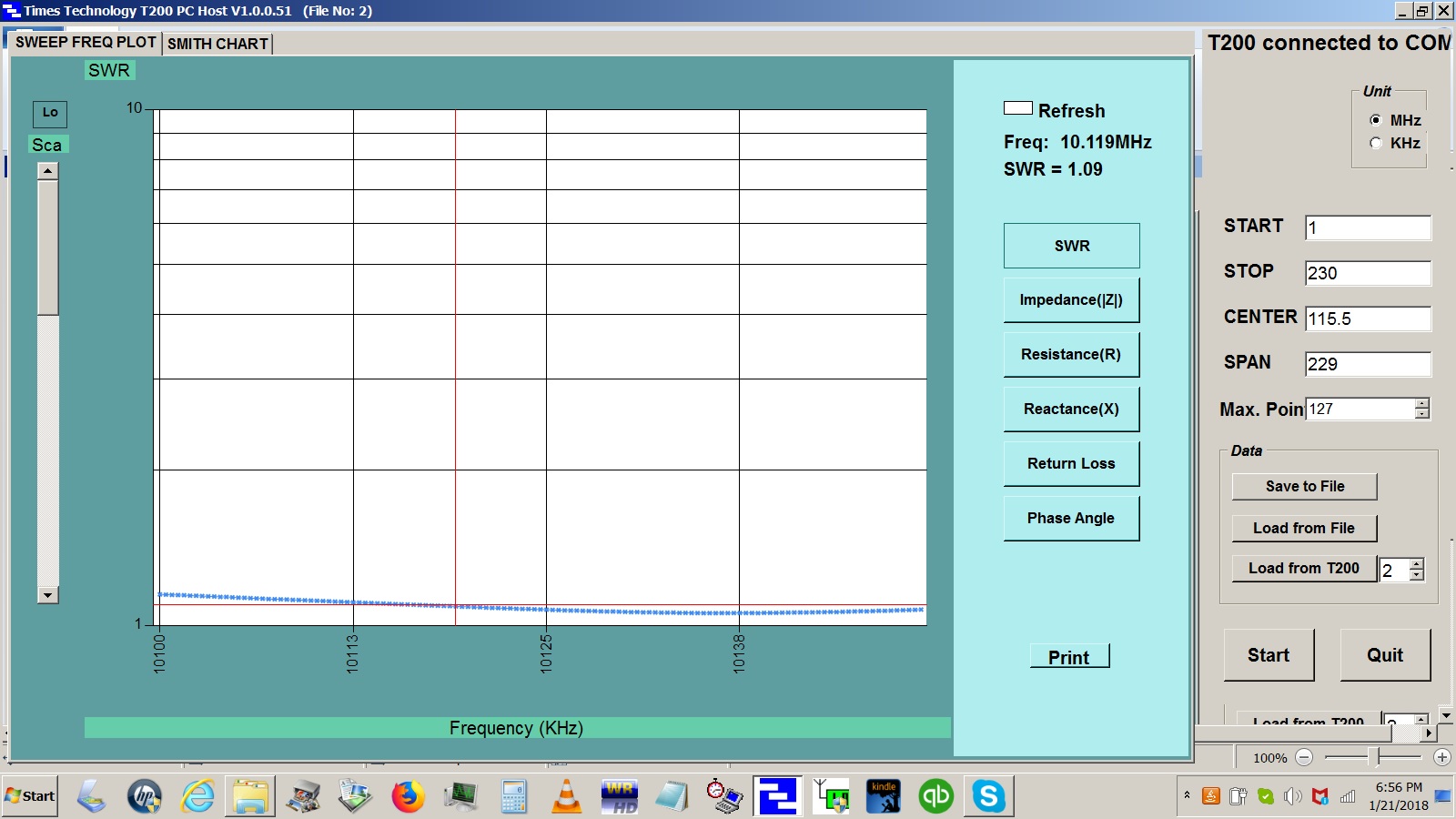

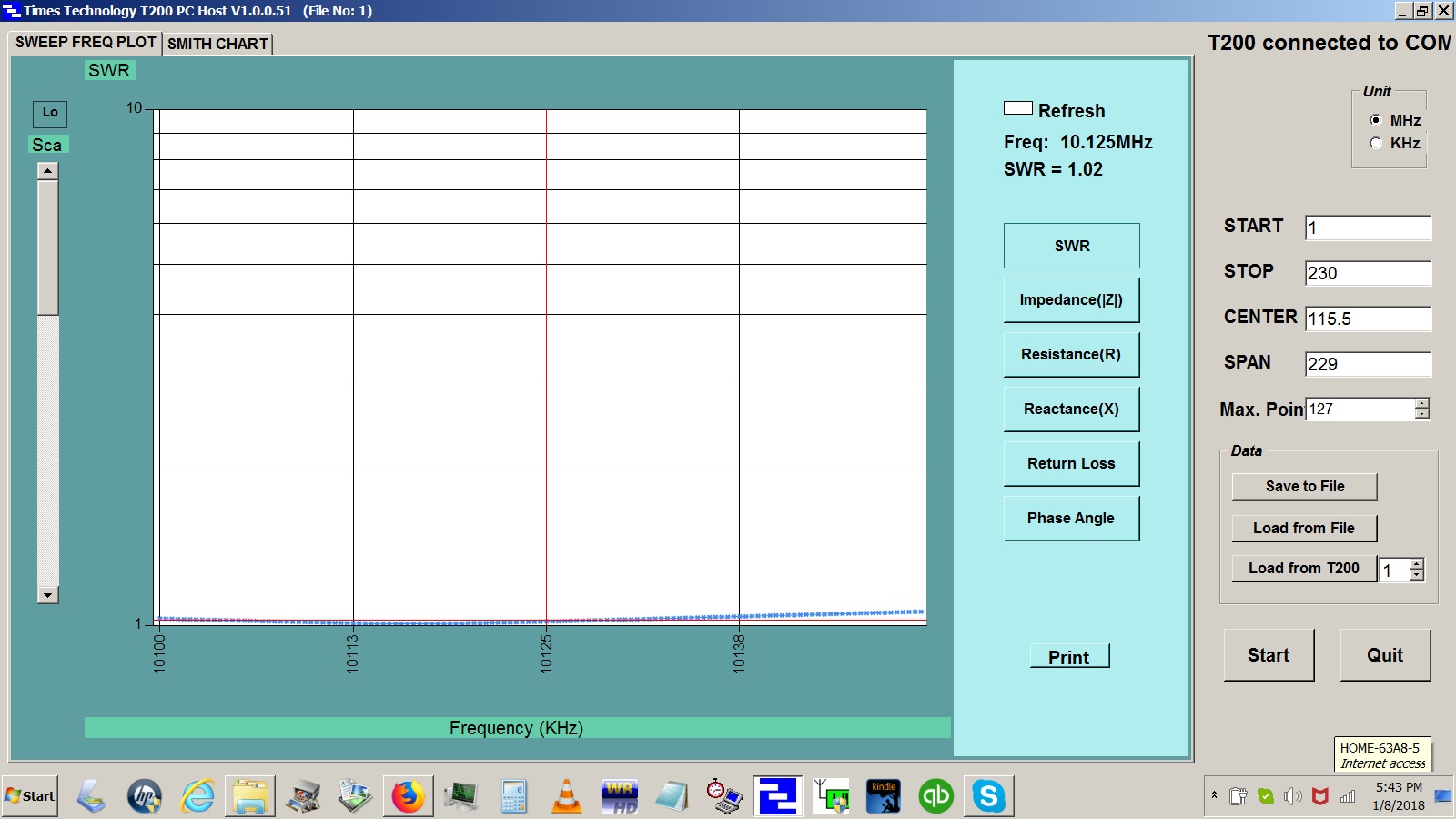

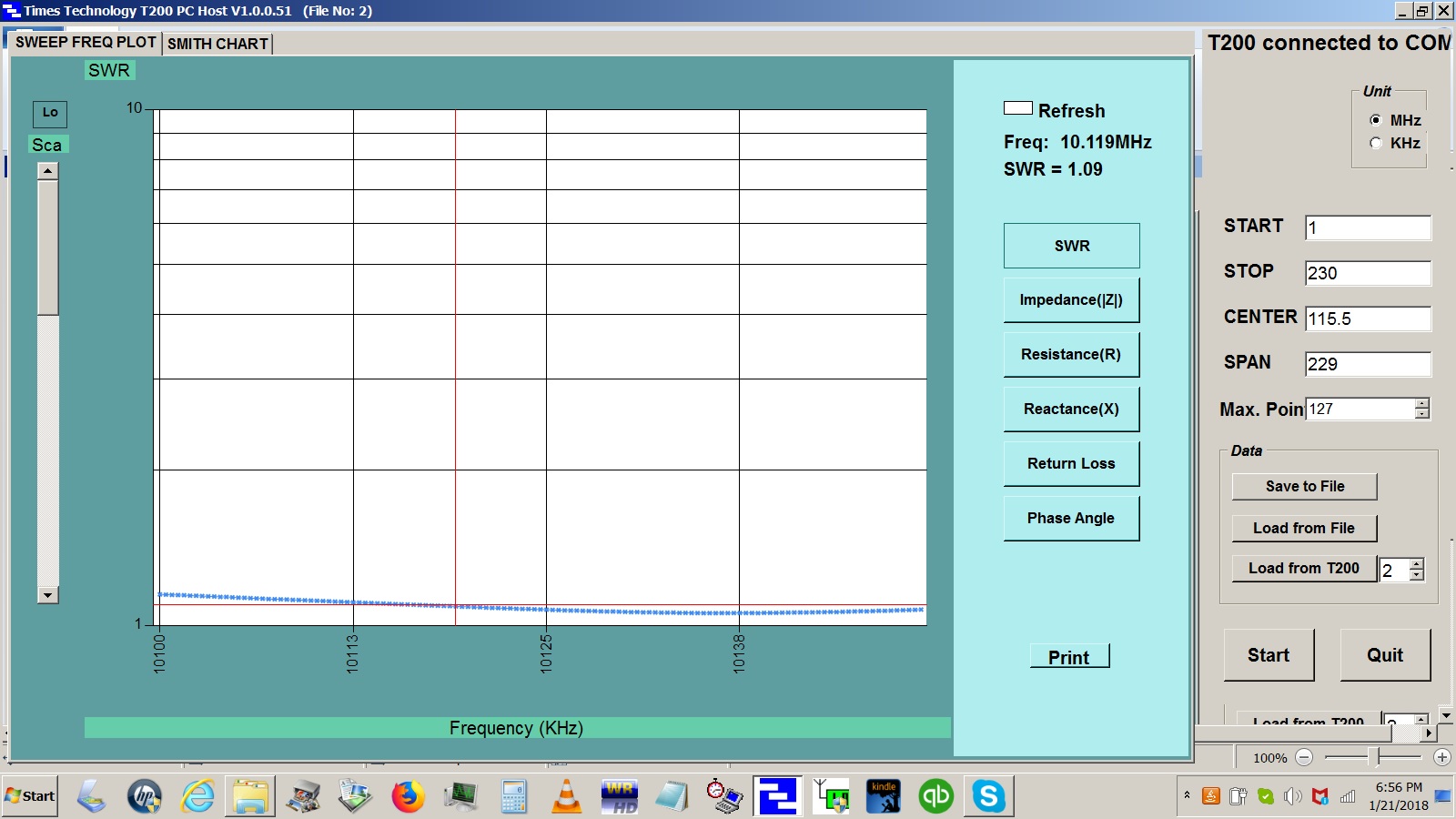

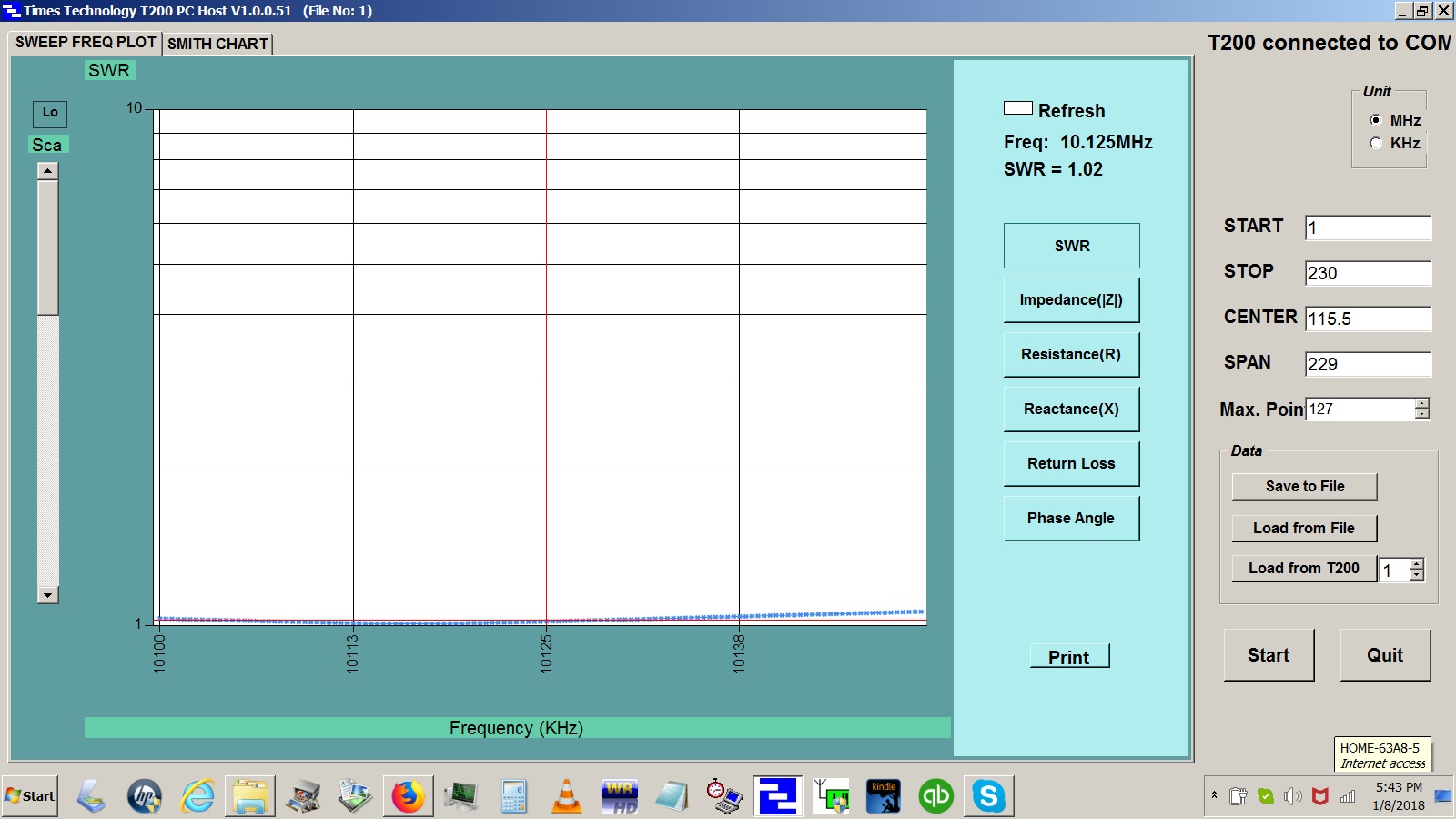

The VSWR performance of the 30m L-matching network is shown in Figure 10. Excellent performance has been achieved over the entire band after lab tuning. Figure 10. VSWR Performance of the 30m L-Matching Network. Excellent performance has been achieved over the entire 30m Band.

Figure 10. VSWR Performance of the 30m L-Matching Network. Excellent performance has been achieved over the entire 30m Band.

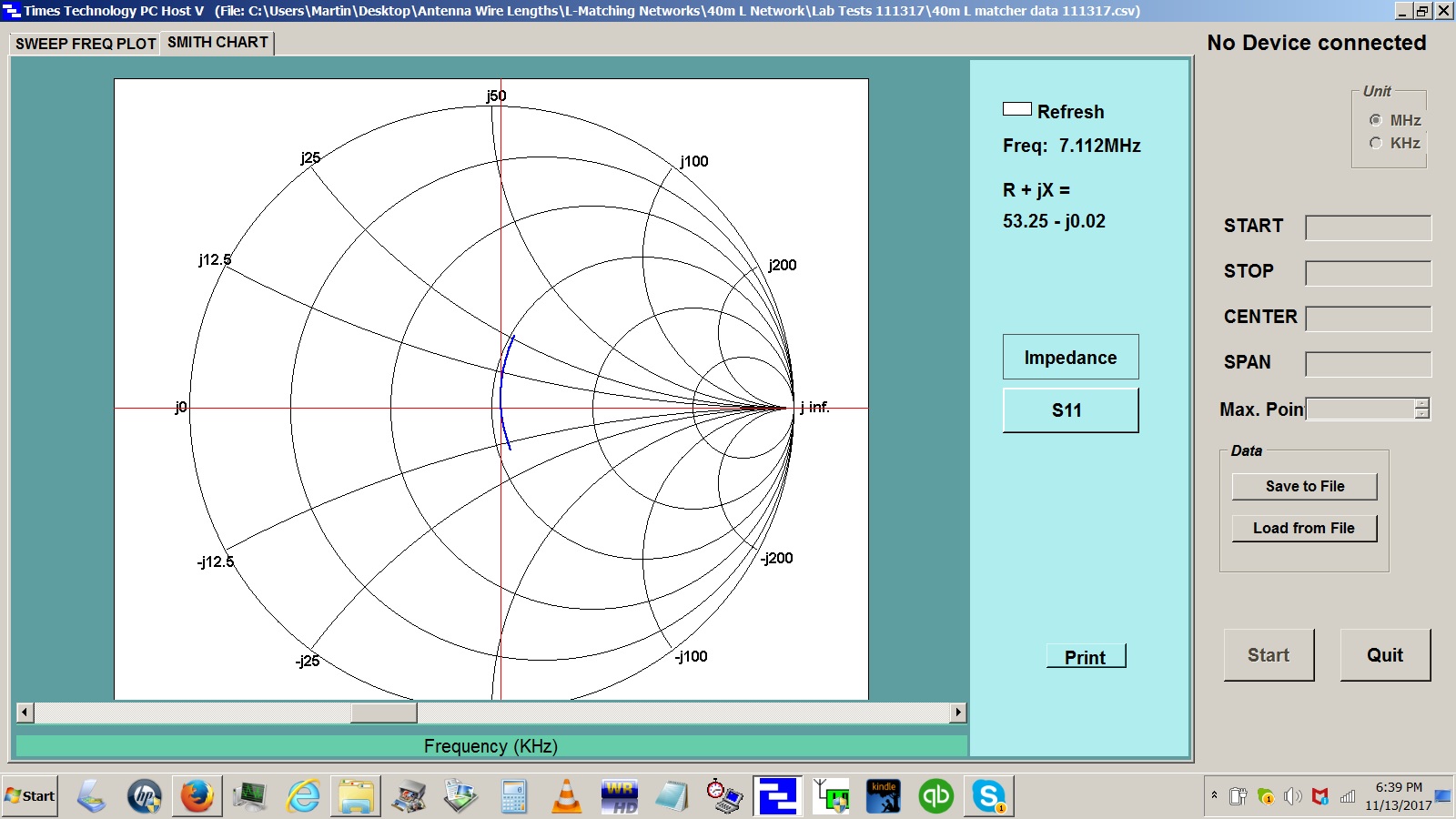

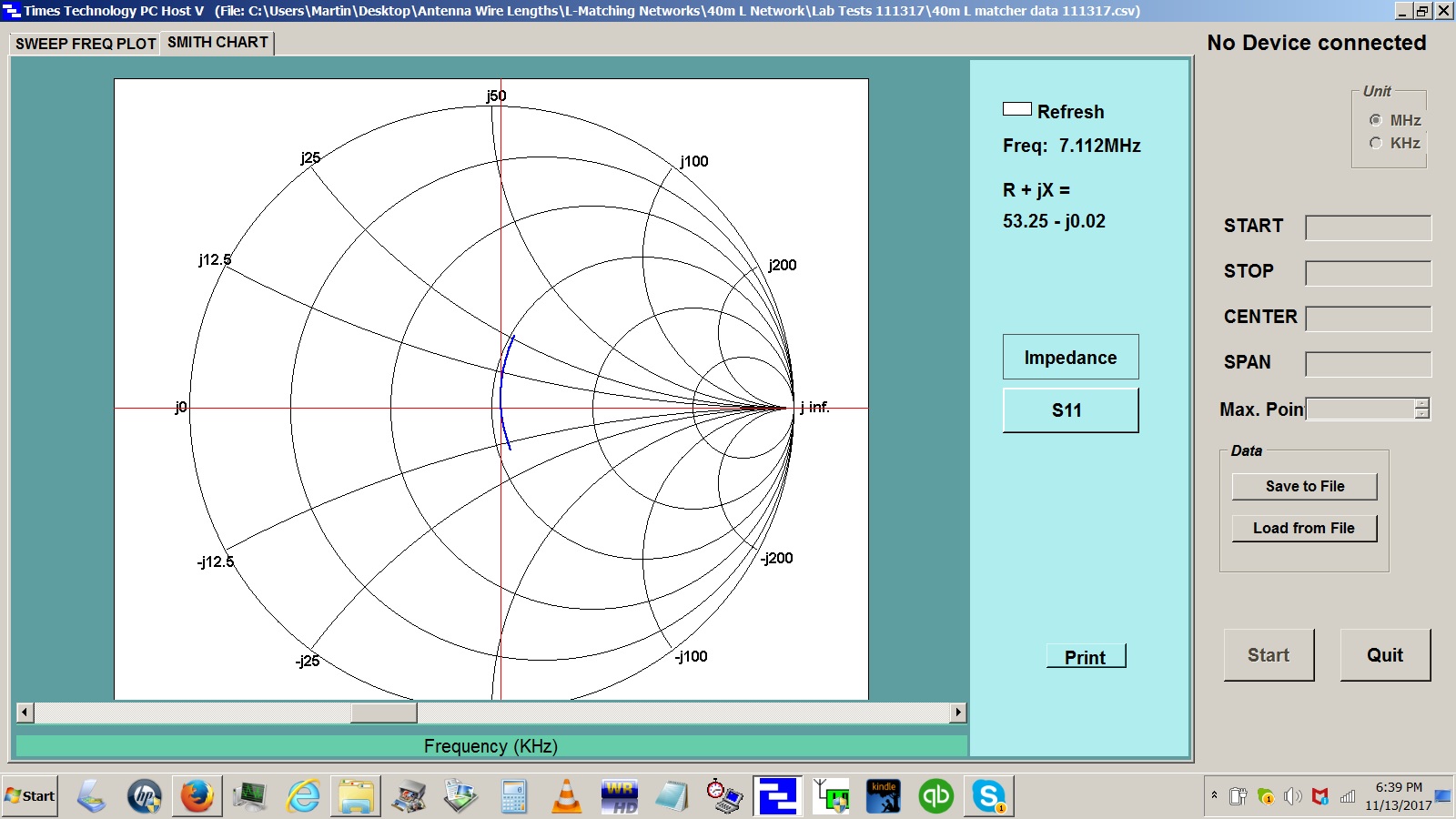

The 40m L-matching network of Figure 6 was tested in the lab. The network was loaded by a 4573-ohm load. The resulting Smith Chart that was swept over the entire 40m band is shown in Figure 11.

Figure 11. 40m L-Matching Network Smith Chart. An excellent match is observed over the entire band.

Figure 11. 40m L-Matching Network Smith Chart. An excellent match is observed over the entire band.

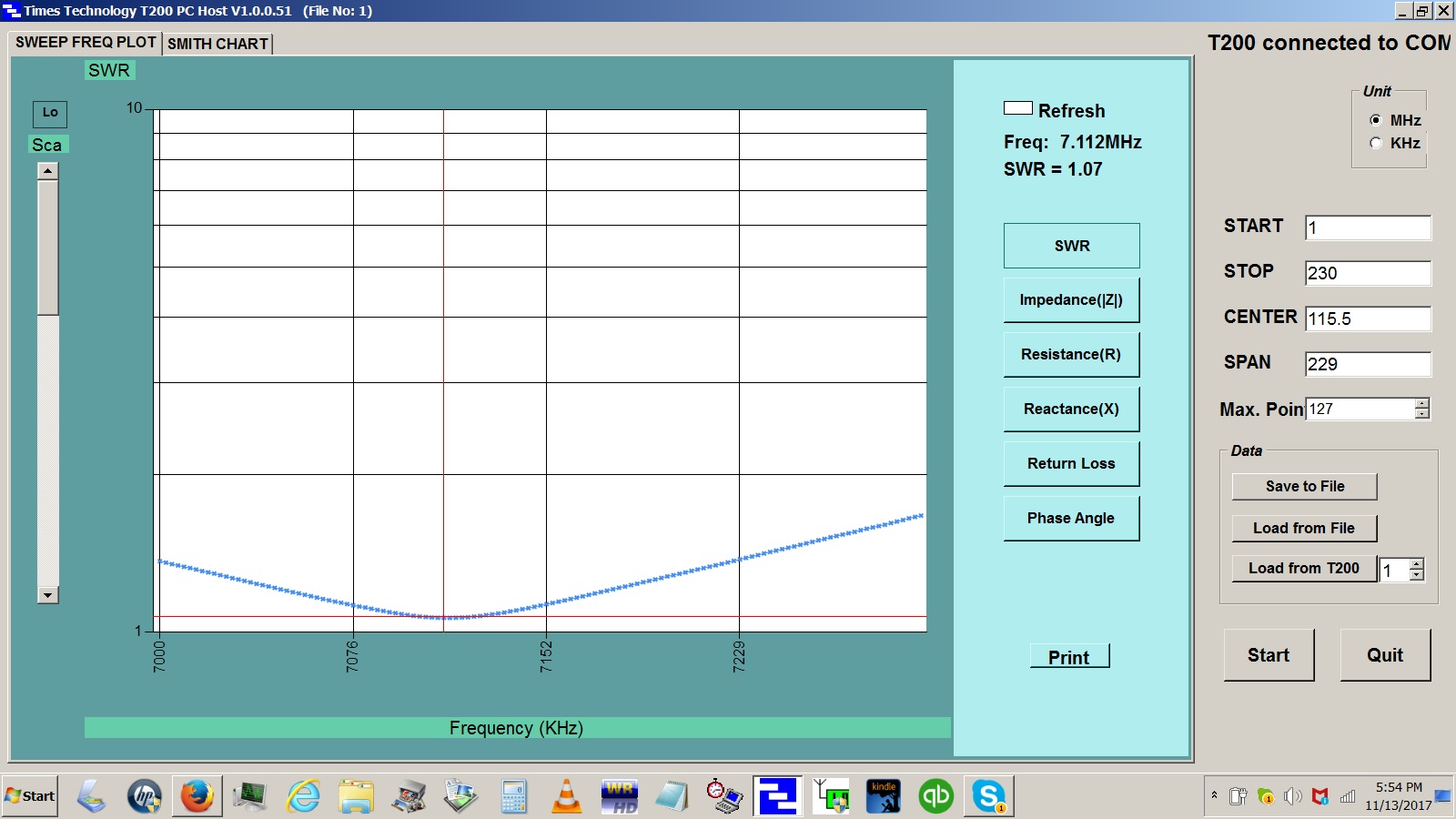

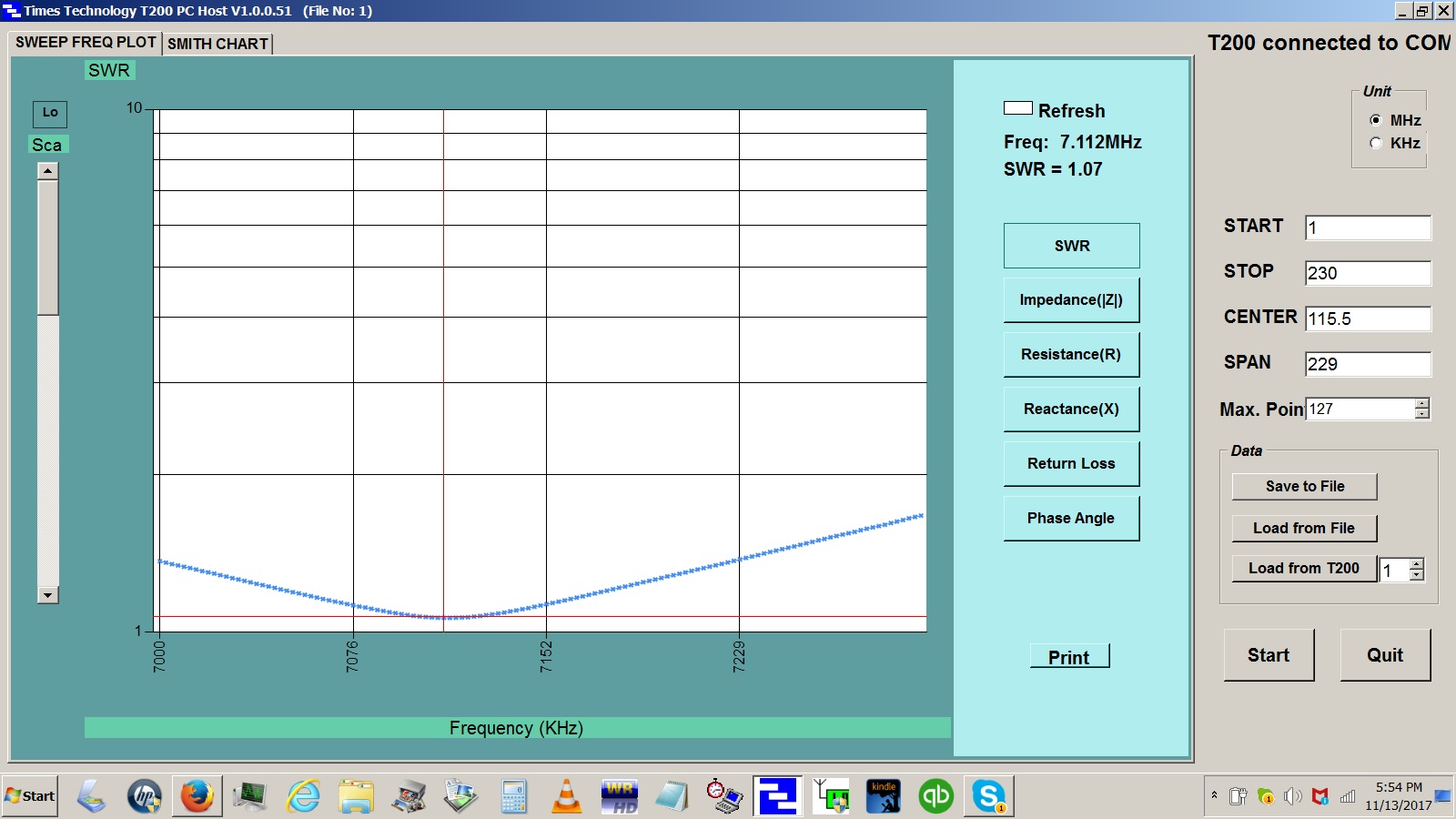

The VSWR performance of the 40m L-matching network is shown in Figure 12. Excellent performance has been achieved over the entire band after lab tuning.

Figure 12. VSWR Performance of the 30m L-Matching Network. Excellent performance has been achieved over the entire 40m Band.

Figure 12. VSWR Performance of the 30m L-Matching Network. Excellent performance has been achieved over the entire 40m Band.

Field-Test Prep

In preparation for field-testing, we will want to prepare the counterpoise that will consist of a length of coax that has been cut to 0.05 wavelength at the design frequency. If the common mode choke will be connected to the L-matching network at the SO-239, a wire should be cut to 0.05 wavelength at the design frequency. A grounding stud should be provided to the network ground for counterpoise connection. This may be a separate ground stud mounted on the case and connected to the SO-239 connector flange, for example. Please refer to one of the interconnection diagrams for the counterpoise connection point.

Field Test Procedure

In order to test the EFHW antenna with an L-matching network feed, two end supports will be necessary. The supports may be a pair of nearby trees, a pair of telescoping masts, or one of each. Each support should be fitted with a halyard so that each end may be raised and lowered. Ideally, testing should be performed at least 0.25 wavelength above ground, except, of course, for the case of an inverted-L. The L-matching network and common mode choke will be heavy, so the end support has to be sturdy enough to support the weight of the transmission line, matching network, counterpoise, and choke. Once that is arranged, testing may begin.

Without altering the L-matching network or counterpoise in any way, the length of the antenna wire should be pruned to cancel any remaining reactance at the design frequency as viewed on the antenna analyzer. Once that has been accomplished, the real part of the impedance may be read. It should be close to 50 ohms. If it is not, then we know that we have chosen the incorrect impedance transformation ratio and, consequently, the incorrect value for unloaded Q.

Figure 13 shows the field-test Smith Chart for the 30m L-matching network. The swept measurement places the cursor very close to the center of the Smith Chart. The actual performance is very good for the entire 30m Band. Figure 13. Field-Test Smith Chart for the 30m L-Matching Network. Measured performance is very good over the entire 30m Band.

Figure 13. Field-Test Smith Chart for the 30m L-Matching Network. Measured performance is very good over the entire 30m Band.

The field-test VSWR performance of the 30m L-matching network is shown in Figure 14. Excellent performance has been achieved over the entire 30m Band.

Figure 14. Field Test VSWR Chart for the 30m L-Matching Network. VSWR performance is very good over the entire 30m Band.

If the VSWR is satisfactory, testing may be completed. If it is not, iteration is the next step. Usually, the real part of the transformed antenna resistance will hint at whether we have chosen a transformation ratio that is too high or too low.

There is another approach that is worth considering. An L-matching network can be constructed from a tapped series inductor and a shunt air variable capacitor. Calculations may be performed in the field to alter the impedance transformation ratio by adjusting the inductor and capacitor. Once satisfied with the result, the inductor and capacitor values may be made permanent. If you happen to have a home with a second-story window, you might consider stringing the antenna from the window out to a tree or mast. Then, the L-matching network adjustments can be made from the open window. Please take care to keep children and pets away from any open window.

In any event, the antenna wire length will have to be restored to its full starting length so that it may be pruned enough to cancel any residual reactance that might be observed for the iterated L-matching network. Tiny wire rope cable clamps [12] shown in Figure 15 provide a way to splice pieces of wire back onto the antenna.

Figure 15. Wire Rope Clips. The 2mm and 3 mm variety are handy for splicing pieces of antenna wire together.

Figure 15. Wire Rope Clips. The 2mm and 3 mm variety are handy for splicing pieces of antenna wire together.

By now, you have probably figured out how to perform some reverse engineering from the field-test results. If the values of the inductance and capacitance have been determined experimentally, it is possible to work backward to determine the unloaded Q and then the impedance transformation required to obtain a match. From this, you will be able to estimate the end resistance of the wire.

Field Test Results

Some field-test results are summarized in Table 3. Many of the load impedances for the L-matching networks have been iterated, and these values appear in the table. Because of weather considerations on the test range in Florida in spring 2020, the test program was suspended. Nonetheless, all of the networks were tested and iterated, with the exception of the 80m L-matching network. This may have been fortuitous, as there was no means to elevate the 80m antenna to a height exceeding 0.25λ (66 ft) with the masts available.

All of the measurements in Table 3 were made with 50′ of RG-8X coax. The reference plane of each measurement was moved to the plane of the SO-239 connector on each L-matching network by means of an open/short/load calibration load kit.

Table 3. Spring 2020 Field-Test Data Summary. The as-built component values and VSWR results are as reported. The L-matching networks and coax were supported by a 33’ (10m) mast. The mast was judged to be of insufficient strength to support an additional common mode choke. Consequently, all measurements were made with a 50’ length of RG-8X where the entire coax acted as the counterpoise. No attempt was made to optimize the length of the counterpoise. The 80m L-matching network could not be tested because of the weather. See text.

Table 3. Spring 2020 Field-Test Data Summary. The as-built component values and VSWR results are as reported. The L-matching networks and coax were supported by a 33’ (10m) mast. The mast was judged to be of insufficient strength to support an additional common mode choke. Consequently, all measurements were made with a 50’ length of RG-8X where the entire coax acted as the counterpoise. No attempt was made to optimize the length of the counterpoise. The 80m L-matching network could not be tested because of the weather. See text.

References

[1] ARRL Antenna Book, 21st ed., Ch. 7, p. 2.

[2] https://www.eznec.com/

[3] Blustine, M., L-Matching Networks – Field Measurements, March 17, 2020.

[4] https://www.aa5tb.com/efha.html

[5] https://mfjenterprises.com/products/mfj-854

[6] https://web.ece.ucsb.edu/~long/ece145a/Notes5_Matching_networks.pdf

[7] Ibid.

[8] https://home.sandiego.edu/~ekim/e194rfs01/jwmatcher/matcher2.html

[9] https://www.66pacific.com/calculators/coil-inductance-calculator.aspx

[10] http://www.qrz.lt/ly1gp/amidon.html

[11] https://www.66pacific.com/calculators/toroid-coil-winding-calculator.aspx

[12] https://www.amazon.com/Rannb-Stainless-Simplex-Single-Diameter/dp/B07DLVNR54/ref=sr_1_7?crid=26694JFBAHN04&keywords=cable+clamp+3mm&qid=1654922072&sprefix=cable+clamp+3mm%2Caps%2C85&sr=8-7

Martin, K1FQL

Figure 15. Wire Rope Clips. The 2mm and 3 mm variety are handy for splicing pieces of antenna wire together.

Figure 15. Wire Rope Clips. The 2mm and 3 mm variety are handy for splicing pieces of antenna wire together.