Nashua Area Radio Society Field Day 2022

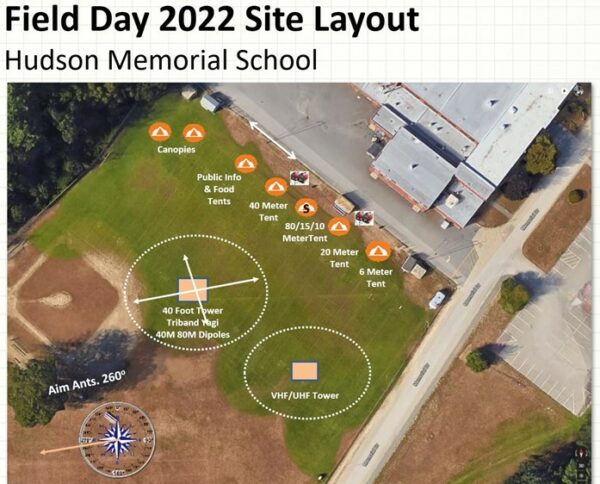

Field Day 2022 is over, creating great memories for all who joined us. We have 47 names on our guest log, including members and visitors. Add to that number our helpful volunteers, and over 70 people participated in Field Day with us. This year we returned to Hudson Memorial School, the site of some of our most ambitious past Field Days. Our current effort was more modest, we would be class 3A, with four radios and antennas to cover 6, 10, 15, 20, 40, and 80-meter bands. Our primary tower was 40 feet tall and held a tri-band Yagi and two dipoles, one each for 40 meters and 80 meters. For 6 meters, we had a loop-fed array on a push-up mast. All of our radios were configured to support all modes, SSB, CW, and Digital. Each station incorporated a laptop PC to run our logging application and support digital modes.

Planning

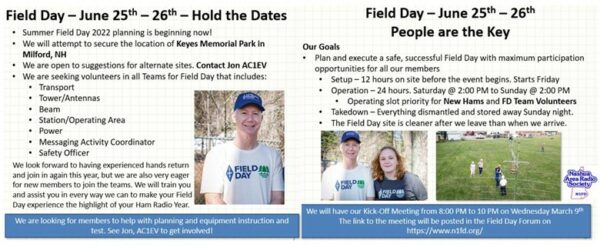

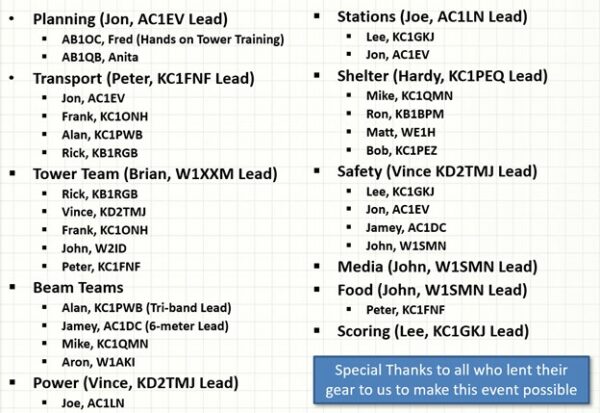

Our Kick-Off Meeting for Field Day was on March 9. There is lots of planning and training to do before the day of the event. Many of our volunteers have participated in Field Day with the club in past years, but this year some of them would become the leaders of their teams for the first time, myself included. Fred, AB1OC, and Anita, AB1QB, would represent the ARRL in their new roles during Field Day and leave their past roles in NARS Field Days for other members to fill. I volunteered to lead the effort this year, and both Fred and Anita generously gave their time and advice to our team to assist with planning and training for the event.

My first efforts went towards finding a group of volunteers who would commit to the project and to securing a venue for the event. In recent years we had successfully held Field Day at Keyes Memorial Park in Milford, NH, but this year it was booked for Field Day. We also had great success with Field Day at the Hudson Memorial School in Hudson, NH so I inquired with them about returning to their site. The school is a friend of NARS, we have done many activities with them, including an ARISS contact, so they made it easy for us to engage and obtain approval to use their field. Special thanks to Principal Keith Bowen for making this painless.

The Field Day 2022 Teams

We had 20 members volunteer to support our Field Day effort from planning in the beginning to putting the last bit of gear back into storage on Sunday night after the event. Other members assisted as they could during planning or the during the event itself. While NARS owns a lot of the gear we used for Field Day, we do not own any radios or peripherals. We are very fortunate to have members who generously lent their radios and other gear to the cause. In our first few planning meetings, we took stock of our team’s skills, experience, and preferences and sorted ourselves into functional teams. We were fortunate that each team leader had the basic skills and experience needed to assume their role. We would arrange training where needed and documentation from past field days to take advantage of hard-won knowledge from past efforts. The teams broke down as follows:

Transport Team

NARS has a storage trailer where we keep all of our gear that does not require a climate-controlled environment. Much of this gear is only used for our Field Day activities. On Field Day, our day begins here, the Transport Team gathers, and the other Team Leads make sure that all of the material they will need at our Field Day site is loaded onto the trucks. We are fortunate that we have many members with pickup trucks, and we also have a number of trailers available. We spent around 2 hours at the trailer on Friday morning loading the trucks with our gear. This year our Field Day site was only a 15-minute drive from our store. Murphy loves Field Day, so we did make a return trip to the trailer to pick up additional material before the day was done.

Once we arrived at Hudson Memorial School, we were able to unload and stage our equipment on the field prior to beginning setup. Most of the team members from the other functional teams were there to assist, and the job was done very quickly.

Shelter Team

On March 15th, 7 members of the Nashua Area Radio Society met at BOB, our storage location for club gear, to do an initial gear test and evaluation to begin our hands-on preparation for Field Day.

This gave the Shelter team a chance to set up all of the tents we would use and confirm that everything was in order and identify any gaps. We also inventoried tower and antenna components to prepare for future training. A more detailed article about this is here:

Gear Test and Evaluation for Field Day 2022 – Nashua Area Radio Society (n1fd.org)

Tower Team

As we met each week and worked out our upcoming tasks and responsibilities, we also uncovered areas where we needed to fill gaps in knowledge and skills.

One such area was in the Tower team. Everyone on the Tower team had experience from past Field Days, but all had worked under a team leader who was no longer going to be active with us in our efforts this year. Fred, AB1OC, led the team in the past and offered to provide us with hands-on training for erecting the tower and antennas in May. This would give us the perfect opportunity to actually raise the tower, assemble the antennas and confirm that we had all of the assembly steps properly documented and that we had all of the required parts and materials available as well. We met at BOB on May 11 and had a full-scale dress rehearsal for the Tower and Beam teams. You can read about this event in this article:

Hands-On Tower and Beam Antenna Training for 2022 Field Day (n1fd.org)

Beam Team

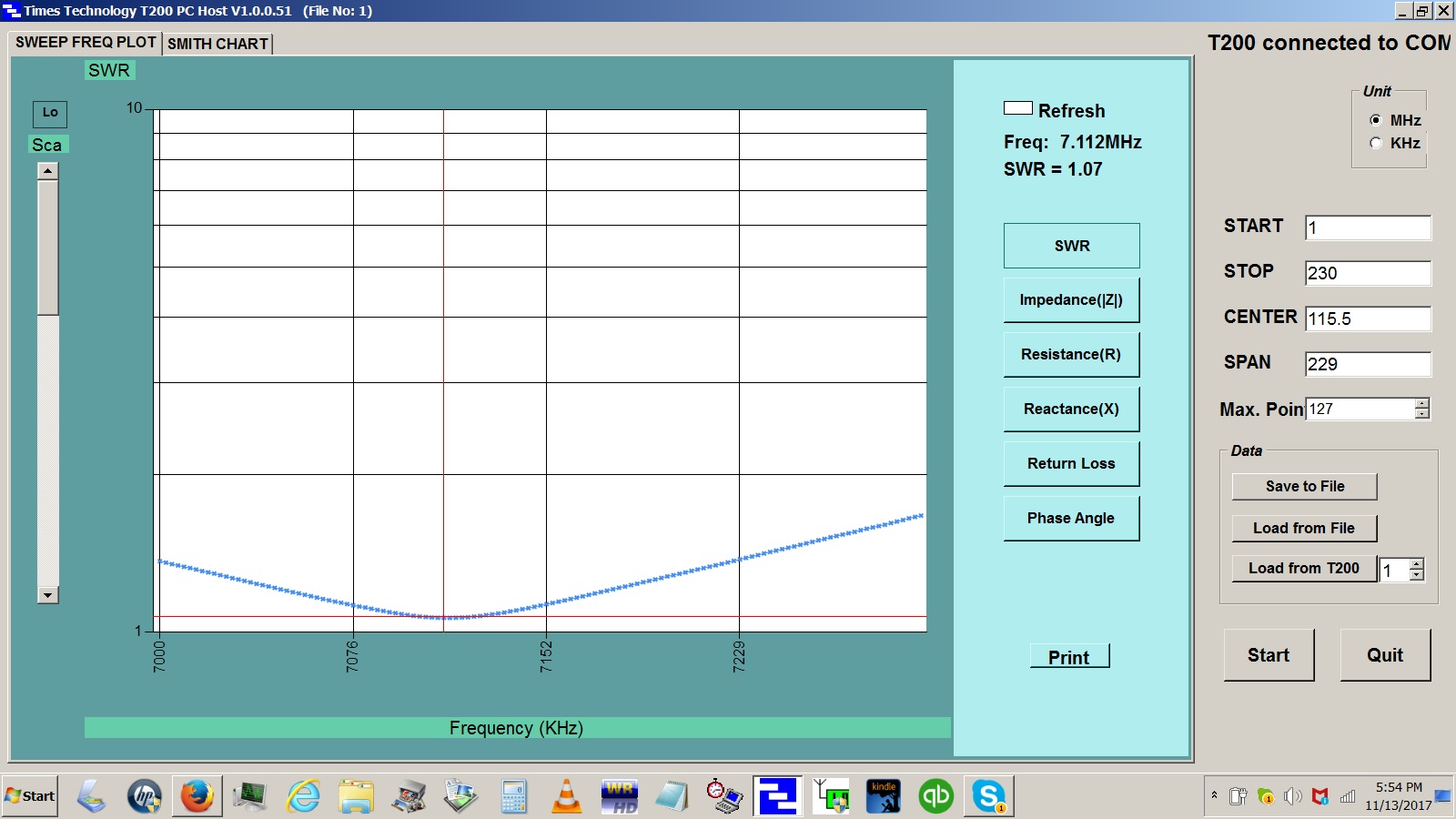

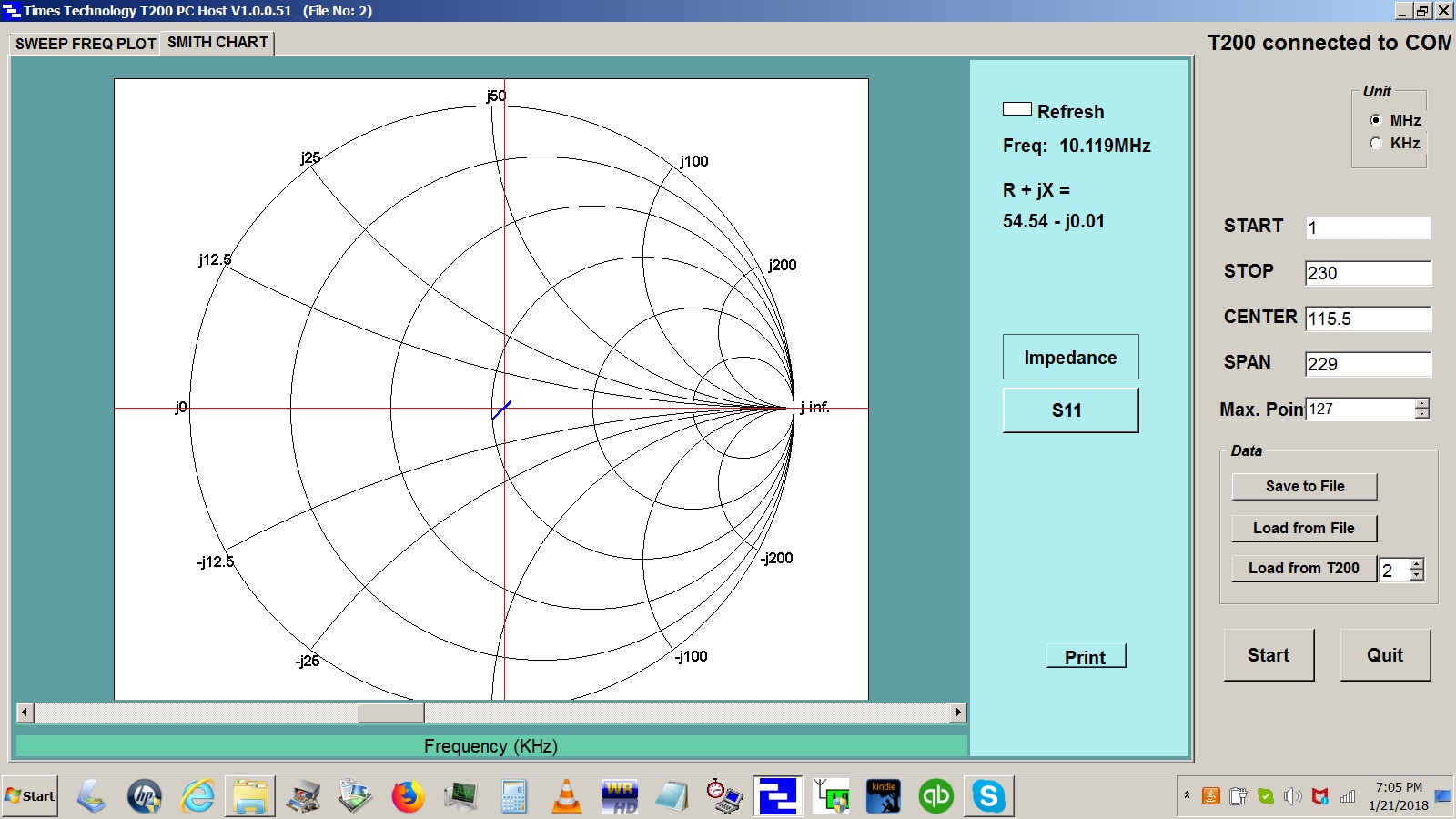

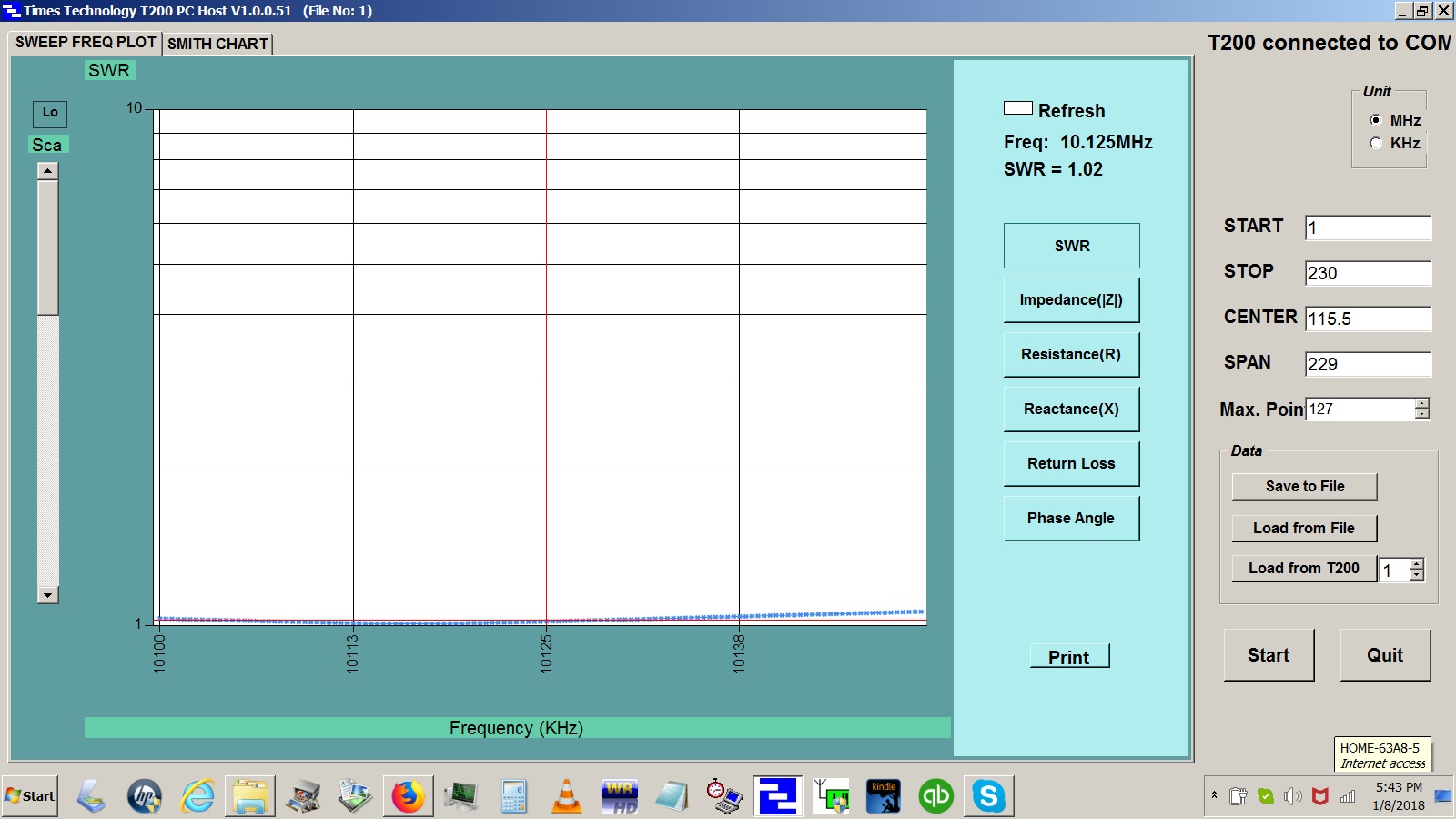

The Beam Team is responsible for assembling the antenna and making sure it is properly in tune for each band prior to raising the tower. Our antenna is from 2014 and has been assembled and disassembled many times over the years. There are many small parts, so the team performs the assembly on sawhorses placed on tarps. This allows for easy retrieval of any parts that may drop during assembly. When the beam is completed, they sweep it with an SWR meter to confirm it is in proper tune. This beam antenna covers 10, 15, and 20 meters.

Once tested, the assembled antenna is carefully mated to the mast on the tower and the coax is attached.

Station Team

The Station Team also had a complex task to complete. As a 3A Field Day station we would have 4 radios in operation. We were going to have each radio setup in a separate tent with a laptop computer for logging and digital modes, and a Winkeyer and paddles for CW. Each radio is limited to specific bands and the coax to the antennas would be routed through band pass filters and/or a multiplexer and antenna switch on the way to the relevant antennas. Figuring this out on the day of the event was not an option, so we planned on creating a full-scale test setup of the configuration prior to the event. I had experience with this area and had been a station master in a past 14A Field Day with NARS so could help out. Joe, AC1LN volunteered to lead the team and Lee, KC1GKJ joined in to assist. We were able to consult with documentation created in past years and that formed a good base of knowledge for us. We arranged with Fred, AB1OC to have a focused training at his QTH for some of the details of setting up the IC-7300 radios, N1MM+ logger and WSJT-X software along with the Winkeyers and paddles. The goal of that training was to properly configure one radio and laptop and use that setup as a reference to roll out to the other radios. Shortly before the training, I caught Covid-19 and could not attend. Joe and Lee worked with Fred and accomplished the initial goal of setting up the first radio.

Joe volunteered to do the trial setup at his QTH and was able to set up an area in his basement that we could work in. We were able to gather the gear we would borrow for the event and set it all up in the test lab at Joe’s. Thanks to Fred AB1OC, Lee KC1GKJ, Jamey AC1DC, Jack WM0G, Dave K1DLM, and Jon AC1EV for generously loaning their gear to the cause.

Joe, Lee, and I took multiple passes at completing the full setup of the IC-7300s along with the laptops and software to get everything configured properly. There are levels and levels of settings to manage, and we were able to get them ready in advance, so set up at Field Day was just a matter of assembling all of the labeled components. We used the Super Antenna MP1, seen in the background for testing on 20 meters, and Jerry AE7KI, an old friend from Tennessee, gave us an excellent report.

Media, Publicity, and Food

While all of the above activities were underway, John W1SMN was working behind the scenes to promote our Field Day activity. He worked to contact various government officials, news media, and others to invite them to join us on Field Day. He also worked with local businesses to obtain support from them for our efforts. Here are the major donors to our event.

Nashua Area Radio Society is grateful for the support from these businesses, and we presented a certificate of appreciation to each of them to say thank you for supporting us.

Here John W1SMN and I present Bill Wilson, owner of Donna’s Donuts in Tewksbury, MA, with a certificate of appreciation from the club.

Ready to begin

Here is a diagram of our proposed setup at Hudson Memorial School in Hudson, NH. We have done much larger Field Days here in the past, even as large as 14A, so there is plenty of room for our setup this year. As you can see from the following pictures, we were able to make the diagram above into a reality.

Operating

This year NARS is operating in class 3A. This means we are a club and have 4 radios. In addition to our 4 radios that can contribute to our QSO count, we also had another radio setup as a GOTA station. GOTA stands for Get On The Air. This station allowed our visitors to make contacts and join in the fun. No license is required as there is a Control Operator present under whose authority the visitor can operate.

Some of our members came with their children and they were very enthusiastic about making contacts. Day or night, the GOTA station had lots of use. Each GOTA operator received a certificate to commemorate their participation.

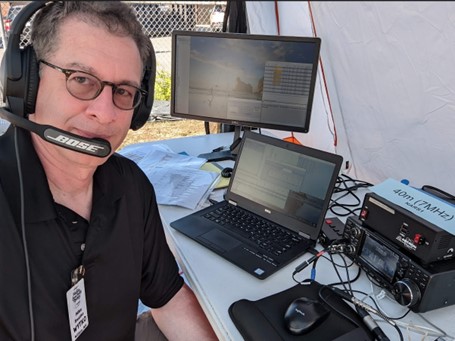

Club members also operated day and night. Each station was configured to cover all modes, so the operator could choose from Phone, CW, or Digital modes. To maintain social distancing in this time of COVID-19, we only had one radio per tent. Here is how each tent was setup. We had an IC-7300, power supply, Winkeyer, paddles, laptop, mouse, and external monitor. The laptop was connected to the IC-7300 and was running N1MM+ and WSJT-X software. All Laptops were networked together including a 5th laptop in our information tent, so we could track our cumulative QSO score in real time.

This being Summer Field Day it was hot during the day. Propagation was good at night, so we had many members operating at that time. Each operating station included a fan and light so we could see what we were doing and stay cool.

Field Day operations last for 24 hours and after that it is time to break down the setup and return everything to its place. We learned in past years that effort spent during this time to stay organized pays extra dividends next year when we do it all over again. Our members really put in extra effort for this, after a few long hot days and even with everyone tired from Friday and Saturday’s work, had enough energy and effort to complete the task. From the end of operations at 2:00 PM on Sunday to the last items stored at BOB and the 6-meter antenna and mast returned to Hollis only took around 4 ½ hours. There are a dozen people in this picture helping with breakdown and others out of view.

Field Day 2022 – How Did We Do?

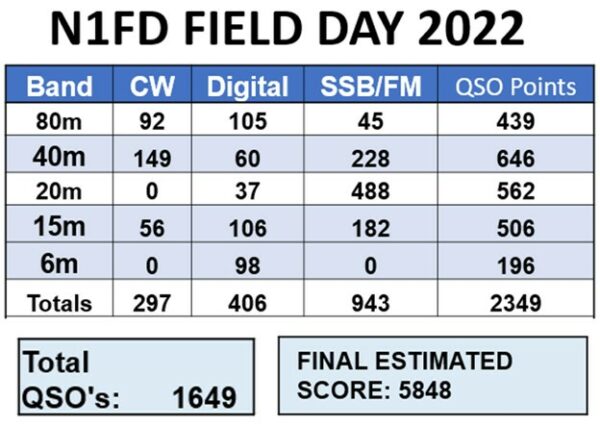

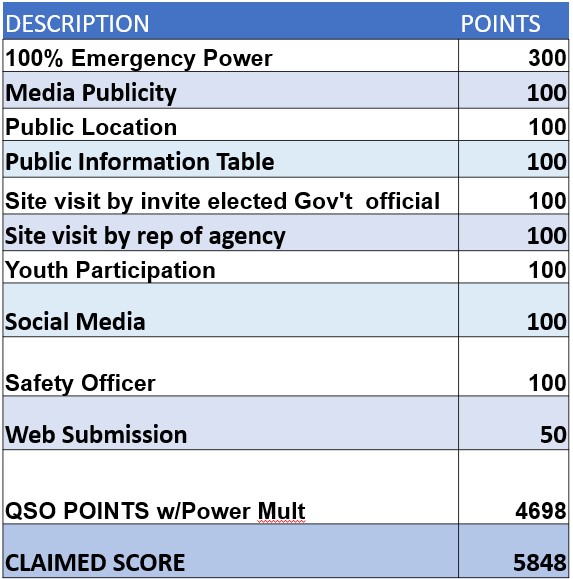

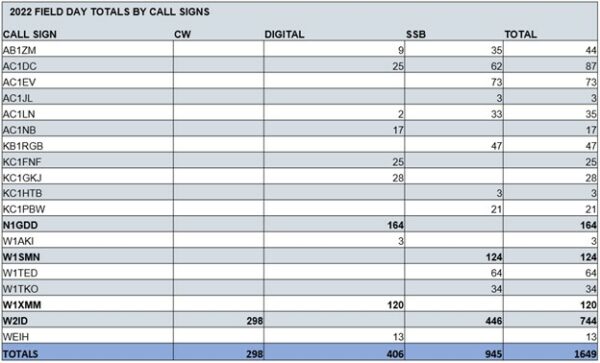

Lots of people had loads of fun! In addition to operating the radios we also learned from every aspect of the event. Field Day is a complex endeavor; we began planning in March and acquired new skills as we progressed towards the day of the event. We worked together and depended on each other. We shared our skills and now those skills are an asset to the club. This year we took training on things we didn’t know and next year we may give training in those same areas to others who follow us. Experienced Hams know that Field Day isn’t a contest, but we do keep score! Here are some of our stats.

Summer Field Day is the highlight of the year for many hams. It is a big part of the history of the Nashua Area Radio Society. It is also a lot of work. When I first joined NARS as an inexperienced ham, I witnessed a very ambitious FD effort with 3 40’ towers, a 60’ tower, a 40 meter V Beam, VHF, and satellite antennas as well. I was very impressed and decided that I wanted to participate in the event the next year. The following year, the club had a similar effort, I think it was 14A and our score reflected our size. Since then, with Covid-19 restrictions and changes in club membership we scaled back our operation. We are fortunate that many of the volunteers who participated this year had experience in past years and were able to assume leadership roles. Our new members are now experienced too, and the club will benefit from the expanded skill sets of its members. We all had fun and working together has given many of us the basis for lasting friendships. We will take advantage of this year’s event to learn from it and apply those lessons to next years Field Day. That’s it for now, 73 and best wishes from

Jon AC1EV

Figure 15. Wire Rope Clips. The 2mm and 3 mm variety are handy for splicing pieces of antenna wire together.

Figure 15. Wire Rope Clips. The 2mm and 3 mm variety are handy for splicing pieces of antenna wire together.