This article discusses how a 3W commercial off-the-shelf (COTS) amplifier [1] may be used to drive a COTS 30W power amplifier [2] for use in a QRP transceiver transmitter. When homebrewing, it can be challenging to determine when to design and build something from scratch or when to assemble it from COTS parts. Several low-power amplifiers were considered for use as driver amplifiers, and the one selected is capable of a 1W (+30 dBm) output with only 0.032 mW (-15 dBm) input, resulting in a 45 dB gain at 10.12 MHz. This amplifier works over the entire HF spectrum. The 30W power amplifier was advertised for use as a linear amplifier that follows a low-power transceiver. It is provided with a receive bypass relay circuit so that the received signal will pass through the linear amplifier unimpeded. The 3W amplifier, however, does not have a receive bypass circuit. To use it in this application, a receive bypass path must be provided. That is the subject of this article.

Component Parts

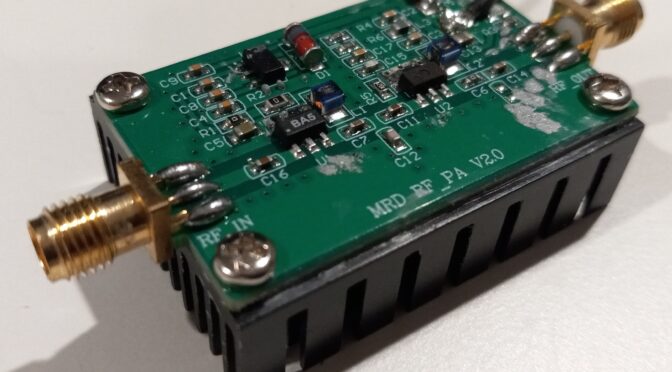

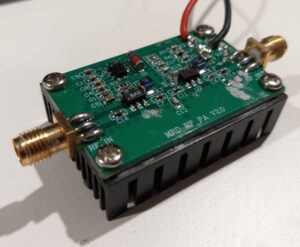

The 3W amplifier selected for this application is shown in Figure 1. It consists of two Monolithic Microwave Integrated Circuits (MMICs) cascaded to produce the specified gain and power output. It was acquired from a seller on AliExpress [3] for less than $15. Upon arrival, the circuit board was removed from its heat sink. That is when it was discovered that no thermally conductive paste of any kind was applied to the interface. The ground tabs on the MMIC amplifiers were designed to dissipate heat. However, the only conduction path is through the via holes in the circuit board in proximity to the ground tabs. This is an ineffective conduction path to the ground plane on the rear side of the circuit board.

Figure 1. A Commercial-Off-the-Shelf MMIC Driver Amplifier. This is a commercially available MMIC amplifier with an advertised output power of 3W. When operated with 12 to 15 VDC, the amplifier overheats. There was better luck once a layer of diamond thermal compound had been spread between the circuit board and the heatsink. Once reassembled onto its heat sink, the amplifier ran lukewarm at an operating voltage of +9 VDC with a power output of 1W (+30 dBm) when driven with 0.032 mW (-15 dBm). If the photo is studied closely, the grey thermal compound may be seen finding its way to the top of the PCB through the PCB via holes. Please click on the image to open in a new screen.

Once diamond thermal compound {4] had been applied to the back of the circuit board, the thermal paste began to fill the via holes thereby increasing the area of the conduction paths to the rear ground plane and to the heat sink beneath.

Next, operation was attempted at +13.8 VDC. While not hot enough to boil water, the heatsink became uncomfortably warm with the module dissipating more than 6W. Clearly, something didn’t seem quite right. These modules were specified for operation between +12 VDC and +15 VDC for the stated output power. The reliability of operation at this temperature was questionable.

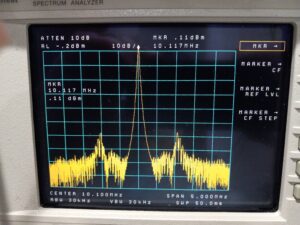

If the heat sink area and volume is not increased, the simplest remedy is to reduce the operating voltage. Operation at +9 VDC was investigated with very good results. The RF power output of the module at 10.12 MHz is shown in Figure 2. The modulation sidebands are due to the bench switching power supply used. An output power of 1W (+30.11 dBm) was achieved for 0.032 mW (-15 dBm) input power, and the power dissipation dropped to 3W. One watt is more than enough power to drive the power amplifier to 10W (+40 dBm). When cooled by the fan in the transmitter, the MMIC driver amplifier will operate reliably.

Figure 2A

Figure 2B

Figure 2. Output Power of the 3W MMIC Driver Amplifier. At A, the spectrum analyzer photo is of the amplifier output power at 10.12 MHz. The modulation sidebands that originate with the switching power supply are visible. An output power of +0.11 dBm is observed. At B, since a 30 dB attenuator protects the spectrum analyzer input, the actual power achieved is 1W (+30.11 dBm) for -15 dBm input power. The gain at +9 VDC operating voltage is 45 dB. This is 10 dB higher than the specified gain, at least at 10.12 MHz. Please click on each image to open in new screens.

The 2-channel relay selected for this application is shown in Figure 3. These are commonly referred to as Arduino relays. Typically, they are operated from the TTL outputs of an Arduino after inversion. The relays may be operated with positive logic or negative logic by moving a small jumper. The relay inputs are optically isolated which greatly simplifies their use.

Figure 3. A 2-Channel Arduino Relay. These relays are optically coupled and can be controlled with positive and negative logic by moving the tan jumper that is visible in the photo. This module consists of two discrete, individually controllable single pole double throw (SPDT) relays. Please click on the image to open in a new screen.

Voltage regulation is provided by the LM317 adjustable voltage regulator [5]. The ripple output of the device is not of concern because it is being operated from a bench power supply. The voltage adjustment potentiometer has been bypassed; nonetheless, since the ripple voltage tends to increase with increasing adjust resistance.

A 2N7000 MOSFET is selectable at the logic input to the relay pair. If selected, it serves two purposes; a high impedance logic input for CMOS as well as a method for logic signal inversion, if desired, at the relay input.

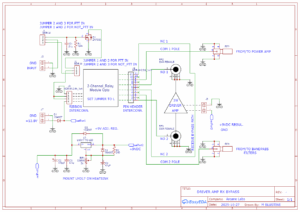

Circuit Design

The circuit was designed on EasyEDA [6], a free, easy-to-use online design software package. As is usually the case, the Gerber files were transmitted to JLCPCB [7], a printed circuit fabrication house in Hong Kong. Turnaround time is typically 5 to 10 days depending upon the complexity of the circuit.

The circuit schematic diagram is shown in Figure 4. All of the key components of the previous section are shown on the schematic. Note that the receive path is through the normally closed contacts of the relays. Thus, no relay coil current is required during receive.

Figure 4. Driver Amplifier Receive Bypass Schematic Diagram. The module has been designed around readily available COTS component parts. All parts are of the through-hole variety since there is little area to be gained through the use of SMT because the amplifier and relay are so large. Please click on the image to open in a new screen.

The jumpers for logic high input and logic low input operation are shown next to J1 and J3. Some of the connections to the relay are made with pin headers and Dupont ribbon wires. Power connections to the driver amplifier are made by connecting wires to screw terminal, J8.

Through-hole components are used in construction. Surface mount (SMT) parts would not reduce the area of the circuit board by much because the 2-channel relay board and 3W driver amplifier are relatively large, and the driver amplifier connects to the circuit board with right angle SMA adapters.

Two SMA connectors provide circuit I/O. SMA connecter, RF4, provides the interface to the transceiver bandpass filters while SMA connector, RF1, provides the interface to the power amp.

The relay coil is operated with supply +13.8 VDC while the driver amplifier is operated with regulated +9 VDC.

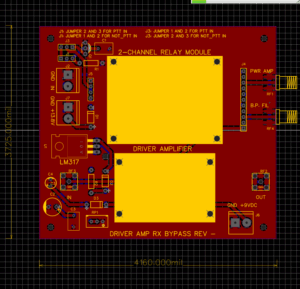

The circuit board layout is shown in Figure 5. Places for the 2-channel relay with mounting holes and the driver amplifier with mounting holes are provided. The driver amplifier will be connected to the PCB with right angle SMA-male to SMA-male adapters.

Figure 5. Driver Amplifier Receive Bypass Circuit Board Layout. This is the silkscreen view of the assembly. The dimensions of the board are visible in the photo. Please click on the image to open in a new screen.

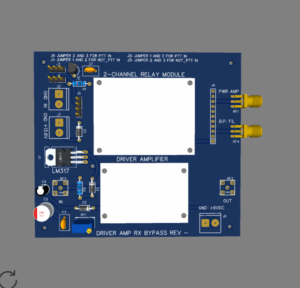

A 3-D rendering of the design is provided in Figure 6. Please note that some of the components are missing because 3-D models were not provided for the entire online library.

Figure 6. A 3-D Rendering of the Driver Amplifier Receive Bypass Circuit Board Layout. This 3-D virtual reality image was generated by EasyEDA. Some of the components are missing because 3-D images of the parts were not found in the library. Please click on the image to open in a new screen.

Conclusions

A design has been described that may be useful in conjunction with just about any RF amplifier for use in ham radio transceivers. The amplifier receiver bypass described in this paper will permit bi-directional operation as is required in one direction on transmit and the opposite direction on receive.

References

[2] https://www.aliexpress.us/w/wholesale-30W-shortwave-amplifier.html?spm=a2g0o.productlist.search.0

[3] 3W shortwave amplifier. Op. cit.

[5] https://www.ti.com/lit/ds/symlink/lm317.pdf

Disclaimers

This circuit design is provided for informational and educational purposes only and is supplied “as is” and without warranties of any kind, express, implied, or statutory. No representations or warranties are made regarding the accuracy, adequacy, completeness, legality, reliability, or usefulness of this information, either in isolation or in the aggregate. This circuit design may contain links to or information based on external sources or third-party content. Endorsement and responsibility for the accuracy or reliability of such third-party information or for the content of any linked websites are not taken.

There has been a question concerning DC bias to this circuit. One might infer from the schematic that the linear RF Driver Amplifier receives DC bias continuously from a +9 VDC voltage regulator when, in fact, the entire circuit is only powered when the radio is in transmit mode.

This PCB requires a revision to add receive bypass path grounding upon transmit. The ungrounded receive bypass path during transmit leads to driver amplifier instability. The revision requires extra relay contacts. The revision will be posted once testing has been completed.