Forum Replies Created

-

AuthorPosts

-

February 6, 2021 at 10:26 am in reply to: ARISS Contact Friday February 5th Will Be Heard Over New England #112128

Congratulations to Fred, school, and the students, it went perfectly from start to finish.

I was able to copy most of the downlink with just a HT and a whip.

Hello Ryan,

A low horizonal antenna is omni directional. Low is less than 1/2 wave high, the further it is below 1/2 wave the more Omni it is and the “take off” angle also increases. At or below 1/4 wave high in the lower bands it will be a omni cloud burner and good for NVIS.

You have to consider which band you are evaluating. A 1/2 wave on 40m is 66 ft while on 10m it is 15ft.

As the slope of the antenna increases it will begin to perform more like a vertical. The radiation will be more in the direction of the wire and less broadside. But the take off angle will be lower which is better for DX.

It would be easy to model it in 4NEC2. It is a lot easier to play with lengths and heights indoors on the computer than in the snow.

Many of us can help get you started with 4NEC2 or EZNEC2.

Step one is to decide what performance you want and in which bands.

Hello Duane,

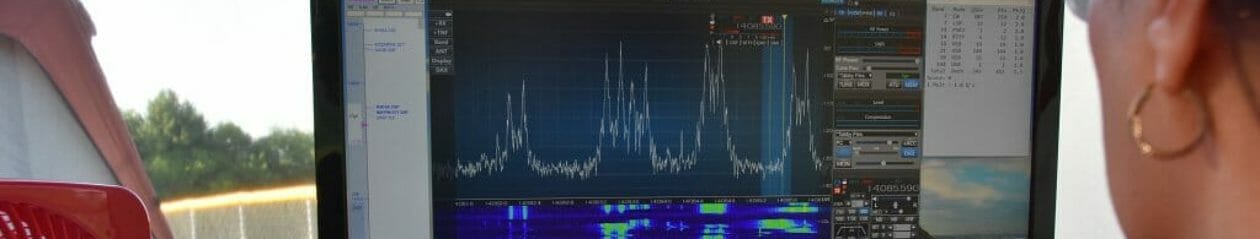

I have played with $20 dongles up to a old Flex 3000 and a Pegasus. The best bang for the buck in my opinion is a SDR play.

The low cost RTL dongles use the chip set developed for TV cable boxes at UHF. Some have a over sampling converter to cover HF with marginal performance. A few have a actual up converter with somewhat better performance, but still marginal.

(The dongles are ok for VHG and UHF, just not HF)

A SDR Play like a RSP-2 has pre-selector filtering over various HF bands to reduce aliasing, a broadcast band overload filter, and covers 500kHz to over 1GHz. There is also a selectable pre-amp.

The software SDR play offers is SDR uno. I also like HDSDR which works with the RSP1. The software is free and includes Omni rig which permits the 991 to be tuned by the SDR display and the SDR to follow the 991.

I use it with my TS-590SG which has a built in T/R switch. I do not recall if the 991 has this feature. If not MFJ makes a box that works well.

The TS-590 is a top performing radio and the SDR Play hears everything it does.

I also use the SDR play for 2m and 70cm receive along with a IC-7100 for transmit to work linear satellites. This setup with the FT-991, SDR Play, SDR Uno, and SATPC32 would be very good for SAT work.

Hello Duane,

The tool Bammi suggests is a good start. I also downloaded a Android phone app called Signal ID that will ID a few signal types.

For signals like FT-8 and others where a large number of signals simultaneous occupy a 3kHz bandwidth it will be hard to identify by sound or waterfall signature. Each signal is only 50Hz wide total with 8 tones and signals can overlap. This will make it nearly impossible to tell the type of signal by sound or waterfall.

A clue from the waterfall is the length of time they transmit. For example FT-8 is about 15 sec, FT4 is 7 sec and WSPR is 2 minutes.

Some signals like RTTY are alone and you can see the two tones and their separation on the waterfall and they have a unique sound. The amount of tone separation in Hz, and number of tones can give you a clue to the modulation type.

Fortunately many of the modulation types generally stick with the band plan so their frequency is a good starting place. I often rely of the frequency tables in WSJT, HRD, etc to identify digital signals.

It is interesting to find new signals.

73,

Hamilton

Figure-1 did not attach to my prior post, here it is; [attachment file=”103473″]

A linear power supply has fewer parts than a typical switching supply. Astron has a good parts department and will ship most parts at a reasonable price within a day. This includes the complete regulator pcb.

The trade off between a linear PSU and a switching PSU with the same power capability is the linear PSU is larger and heavier due to the large transformer, and its output has less to no RF noise which can be desirable for radios with a pan adapter including SDRs. Switching PSU are typically smaller, more efficient and generate less heat.

Personally I have both types of PSUs in the shack and even with the IC-7300 and a SDR I do not notice a significant difference between PSUs except when it is time to move the heavier linear PSU.

Attachments:

You must be logged in to view attached files.As a linear supply the RS-35(M if it has meters) is mostly a large heavy transformer with a small voltage regulator pcb and a few other components making it easier to troubleshoot and repair than a switching PSU. This can be seen in figure-1.

[attachment file=”astron psu.jpg”]

Here are the troubleshooting steps I used to repair Bob’s Astron RS-35 PSU;

1.) The first step is a quick test. I replaced the fuse, disconnect the PSU from other equipment, and turned on the power. The fuse promptly blew confirming the need for further testing.

2.) I removed the yellow wires from the transformer’s secondary to the bridge and the red wire to the large cap to isolate the primary bridge rectifier.

a.) The power supply turned on without blowing fuse.

b.) The secondary winding voltage was nominal at +34.24Vac. This is shown in Figure-2. Note this is both sides of a grounded center tapped winding. The voltage is +17Vac on each side when measured to ground.

[attachment file=”103361″]

c.) The meter lights illuminated, and the front panel volt meter read 13.8V suggesting the low voltage meter and control circuits are all ok.

d.) With the PSU unplugged the resistance to ground of the red wire disconnected from the bridge going to the large cap should be over 1MΩ to check the cap and NPN power transistors for possible shorts due to failures.

3.) With the PSU unplugged I measured one side of the bridge rectifier for junction voltage (or resistance if a diode setting is not available on your DMM). Vforward = 0.509V is nominal for a high current bridge. This is shown in figure-3. The low junction voltage is due to the low current available from the DMM. Under normal operating conditions a junction voltage of .9V to 1.1V is normal.

[attachment file=”103366″]

4.) I measured the other side of the bridge rectifier for the diode junction voltage (or resistance if a diode setting is not available on your DMM). The Vforward = 0.001V, this side of the bridge had failed shorted. With the two bridges in parallel it is unknown which bridge actually failed. No time was invested in reviewing this further as both bridges are always replaced.

The RS-35(M) is a solid well made PSU and is generally very reliable. I have seen a failed bridge several times before. This is likely due to “current hogging” which can occur if the two parallel bridges are not closely matched for Vforward. The bridge with the lower junction voltage will conduct the majority of the current which will increase its junction temperature further lowering its junction voltage. The current sharing between the two bridge rectifiers will be reduced possibly leading to diode failure.

I will replace the two bridges with one rated for 50A and a 1kV PIV. The other option is to place a 3mΩ 5 watt resistor in series with each bridge to ensure equal current sharing. These ultra low resistance power resistors are readily available from Digikey.<!–more–>

Attachments:

You must be logged in to view attached files.Hello Bob,

I can easily do it, I’m down 101 a few miles in Amherst. Another option is Charlie Dunn, he is also a NARS member.

Hello Jeff,

The guiding principle of lightning protection is if two wires are at the same potential, even if it is 50kV, there cannot be current flow between them. Without current flow there is no heat or damage.

In your case the two “wires” are the antenna and the utility wires including each of their associated grounds. Given your proposed arrangement if the utility wires or your antenna is struck there will be a significant potential difference between these “wires” and significant current will flow, much of it across the operating bench and through your radio.

We will consider the utility service and the feed’s point of entry ground rods first. A typical ground rod to earth resistance is around 10 ohms. With a 10kA strike the voltage at the associated ground rod is (I*R) 100kV while the other ground rod is near zero volts. Assuming the coax is connected to one ground rod and to the radio, and the radio is connected to the utility service either through the shack ground or simply a 3 prong power plug a high voltage will appear across the radio.

A simple solution is to locate the ground buss bar and coax entry near and connected to the utility ground. This isn’t always practical.

Depending on the actual layout of your shack a potential solution is to retain the ground rod, surge protector and buss bar as planned at the feed’s point of entry. The feed and a 4 or 6 AWG ground wire would continue from the buss bar to a station ground It is important this 2nd buss bar is connected to the service ground. From there the feed and ground would continue to the operating position. All of the equipment would be connected to this ground.

All of the wires must be connected together during a strike. Each of the 110VAC lines via MOVs in a surge protector, the radio, computer’s case, and PSU via ground straps, the coax shield and even the coax center conductor assuming a coax surge protector is used, are all referenced to a common ground. The key is all of the wires are at the same potential during an event. It doesn’t matter this voltage could be over 20kV.

A single device on the operating table not on the common ground, for example a table lamp or a wall wart not plugged into the surge protector, could provide a current path and a brilliant arc. USB cables from radios to computers that are not on a common ground are a frequent cause of damage. You need to stand back and consider all of the current paths.

There is a lot more to lightning protection than what I can capture here. The ARRL has a good book on the topic.

Hello Dave,

For the class demo I quickly go through the NEC2 design process and then have the students (pre-covid) extend the element lengths per the design and selecting which end is the front based on element lengths. The process clarifies how to use the NEC2 XYZ data.

The Yagi is driven with a HT (146,5xx MHz) with 1 watt of RF power using coax directly to the driven elements. The SWR is <1.5:1 across the full band.

The receiver is a wooden wand with a dipole that is extended to 468/MHz tip to tip with a incandescent light bulb between the dipole elements.

The students perform the following tests;

Forward Gain: When the Yagi is approach from the front with the wand/diploe the light illuminates at about 20′.

Polarization: As the wand/dipole is rotated towards vertical the light dims. At beyond about 45 degrees it goes completely dark.

Elevation: The NEC2 analysis shows a main beam elevation of about 15 degrees. When the wand/dipole is raised the light gets brighter and is at maximum brightness at about 15 degrees.

Directivity and front to back: When the Yagi is approached from the back the wand/dipole can be brought up to nearly touching the reflector and the light remains dark.

Each test is directly related to a possible question on the Extra test and may help with understanding antenna pattern plots. It is also a fair introduction to NEC2.

If time permits a final test is to set the director to the same length as the reflector. Now the light will not illuminate at the front or rear of the Yagi…but it shines bright when the wand/dipole is held over the Yagi. If measured the SWR will remain good at below 1.5:1 across 2m. This demonstrates the conservation of energy and the fact a good SWR does not always mean a good antenna.

I bought the telescoping antennas with F connectors and bulkhead F connectors on Amazon. The connector mounts are simply pieces of 3/4″ square Al tubing cut 3/4″ long and drill 3/8″dia for the F connectors and 1/8″ dia for a screw into the boom. The total material cost was less than $20.

I would like to hear more about your test.

73

Hamilton K1HMS

Hello Luke,

It sounds like a extra 10dB of gain would make the difference on Tx.

A 3 or 4 element 2m Yagi is an easy antenna to make.

There is a “Tape Measure” version on this web site.

I have attached the charts for the 3el 2m yagi I demonstrate during the NARS license classes. It used ezNEC2 for analysis.

The analysis tool I prefer and typically use is 4NEC2. Unlike ezNEC2 the free version of 4NEC2 does not have a restriction on the total number of element segments and it permits optimization. Otherwise they are very similar to each other.My demo antenna uses telescoping elements from Amazon which are great for a demo but would not do well outside. For actual operational 2m and 70cm antennas I used 1/4″ diameter aluminum tubing (McMaster Carr 7237K28 $7 for 6′) and a non-conductive fiberglass boom.

Another approach is to use aluminum arrow shafts (size 1816) and .24 diameter inserts. The inserts accept a 8-32 threaded rod. It is easy to drill a hole through the boom for the 8-32 metal rod for the reflector and directors and screw an arrow/insert onto both sides. Assuming a non-conductive boom the driven elements uses a 8-32 threaded nylon or PBS rod with the coax attached to the two isolated elements of the driven element.

I hope I have touched on a few of the areas you are interested in. I also hope this generates a least a few question on NEC2 and various construction techniques. Many of us are here and ready to help with NEC2 and assembly approaches.

If it helps we can do a Zoom session on NEC2.

Hamilton (K1HMS)

Attachments:

You must be logged in to view attached files. -

AuthorPosts